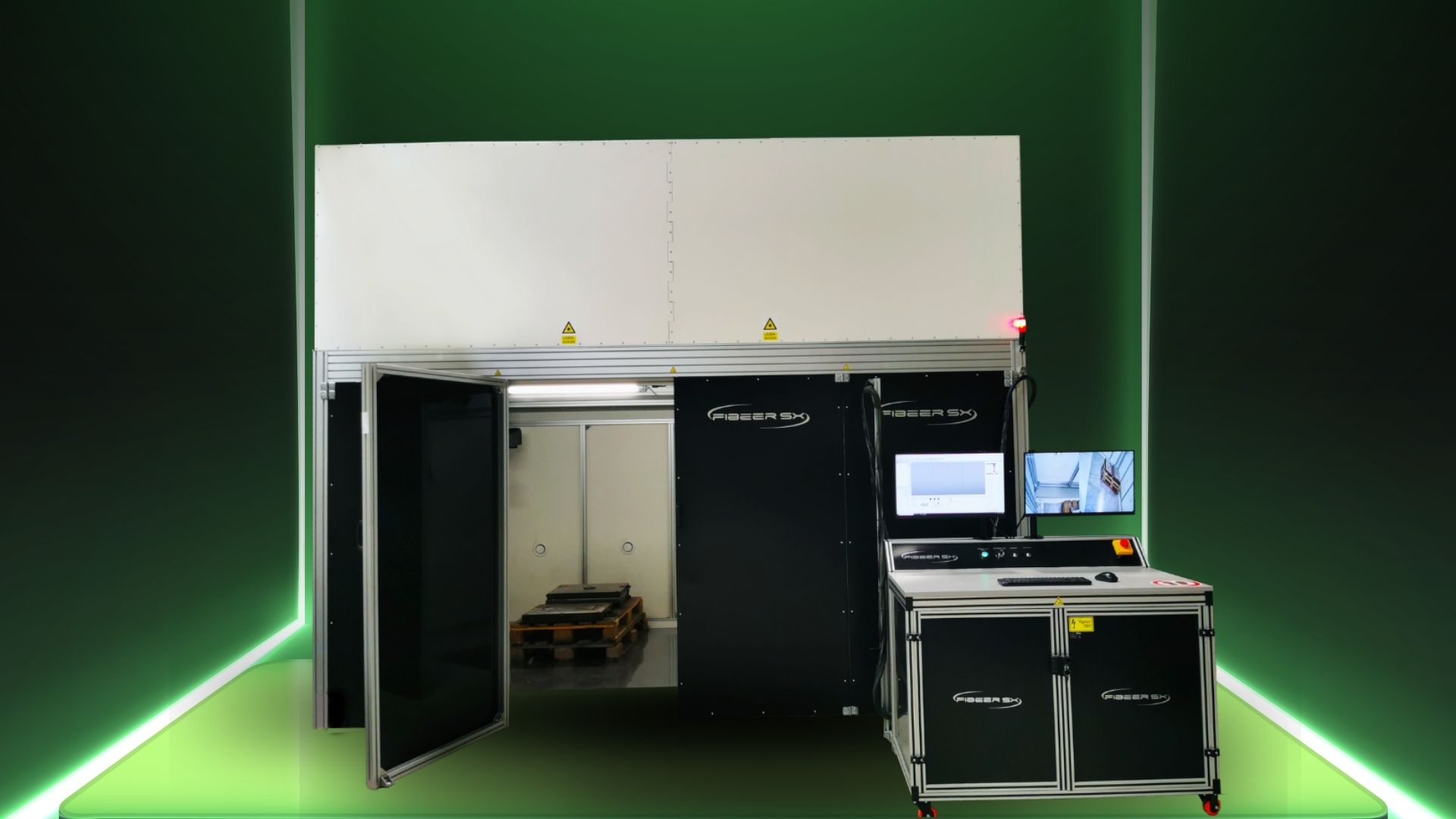

We plan each project taking into account the customer’s needs and the current project announcement. During the planning process, we take into account the specifics of the work processes, the materials used, and the necessary safety regulations. Our individual workstations are fully adaptable, so they can be easily transformed and expanded. We design our workstations with full care and expertise for optimal performance and efficiency, so that fast and efficient work is guaranteed. Individually designed laser workstations are special equipment designed specifically for laser machining processes, for example: laser cutting, laser welding, laser milling. In addition, our laser workstations have a CE certificate, which guarantees compliance with European safety and quality standards. (“This certificate certifies that the products are evaluated against the relevant directives and comply with the new approach directives in terms of safety, health and environmental protection requirements.”)

Personalized design

Functionality is always primary, which is why we recommend testing the desired task as the very first step. When designing the workstation, it is important to consider what type of laser work will be performed on it. For example, laser cutting requires a work surface on which the cut material can be stably placed and fixed.

Furthermore, safety is of utmost importance. This includes the proper blocking of laser beams, the use of protective equipment during laser operations (e.g. safety glasses), and the design of adequate ventilation and exhaust systems to remove gases or dusts generated during the process.

We design the workstation so that employees can work comfortably and safely. This includes height-adjustable work surfaces, which can also be rotated if needed, as well as the appropriate arrangement and grip for tools and materials.

Modern laser workstations often use automated systems to increase accuracy and efficiency. Automated material handling systems are also common, allowing materials to be exchanged quickly and efficiently.

During development, our laser equipment also received software support, which enables precise planning and control of laser machines, even remotely. The integration of design software helps to optimize work processes and minimize errors.