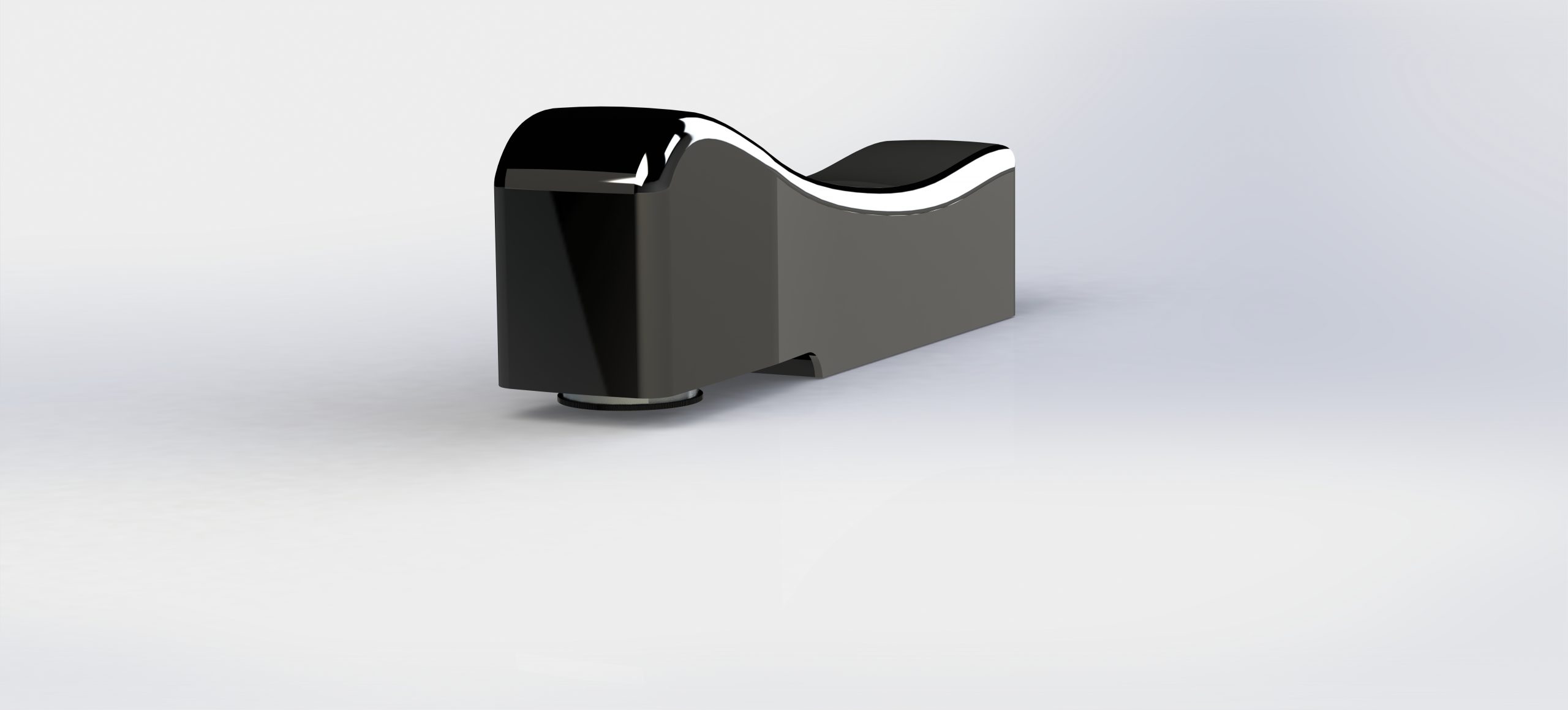

The laser module offers us several possibilities of use. Thanks to the development of FibereSX, we have multifunctional laser devices that can perform several tasks, so they can speed up production processes. Thanks to its user-friendly, compact design, several installation options can be considered. The laser modules communicate with several technologies, now we present the process of the production line installation in the first round.

Installation process and aspects that must be taken into account during integration for proper use. First of all, the specifications and requirements of the laser module must be determined, taking into account the possibilities provided by the production line. Integration areas must be assessed on the production line where the laser module can be installed. There are several options for using the laser module, for example; our individually designed workstation, production line, cells, into an existing machine. During the installation, we pay full attention to occupational safety regulations so that the user can do his work safely. Our equipment has a CE certificate (This certificate certifies that the products are evaluated according to the relevant directives and comply with the new approach directives in terms of safety, health and environmental protection requirements.) The next step is the development of automation and remote control, so that the production line and the laser must communicate with each other and continuously synchronize the necessary data, and can also be controlled remotely. In any case, we recommend that we plan the maintenance cycles together, depending on the use of the laser, in order to increase the life of the equipment and maintain its reliable operation.

Areas of laser use:

1. Material handling and processing

Laser cutting:

Laser modules are often used for precision cutting of metals, plastics, wood, textiles and other materials. In automated systems, laser modules are usually built into CNC machines.

Laser engraving and marking:

Laser modules are used to engrave or mark various materials (e.g. metals, plastics, glass). Such systems can be integrated with automated conveyor belts and robotic arms, thus increasing productivity and reducing the possibility of human error.

Laser welding:

Laser welding provides high precision and speed, which is especially useful in the automotive industry, the manufacture of electronic devices and the production of medical devices.

2. Electronic uses:

PCB (Printed Circuit Board) Manufacturing:

Laser modules are used for precision drilling and cutting in PCB manufacturing.

Micromachining:

Laser modules perform micrometer machining with high precision, which is particularly important in the production of electronic devices and medical instruments.

Robotics and Automation:

Laser modules can be used at the end of robotic arms to perform precision tasks such as cutting, welding, marking.