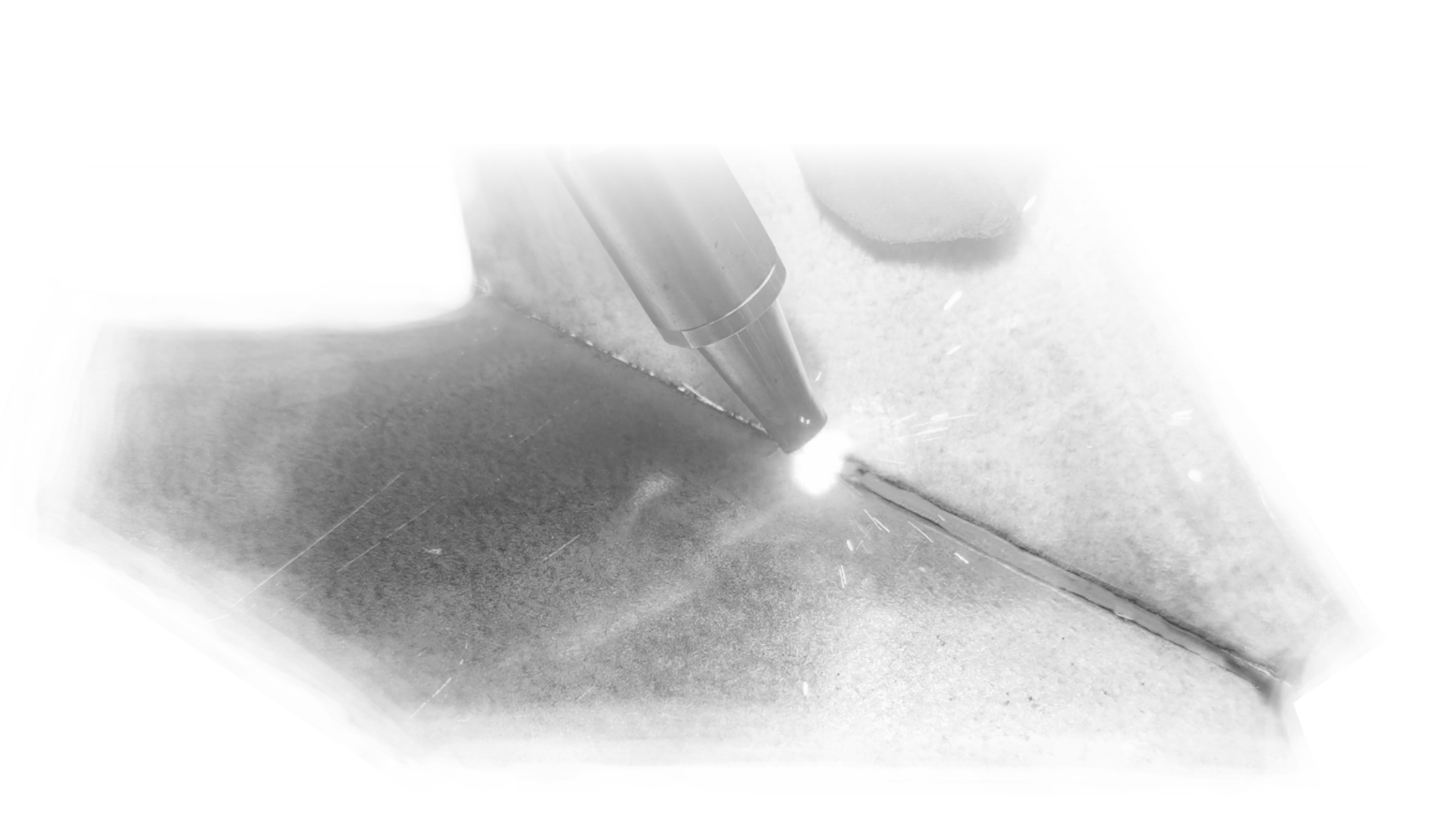

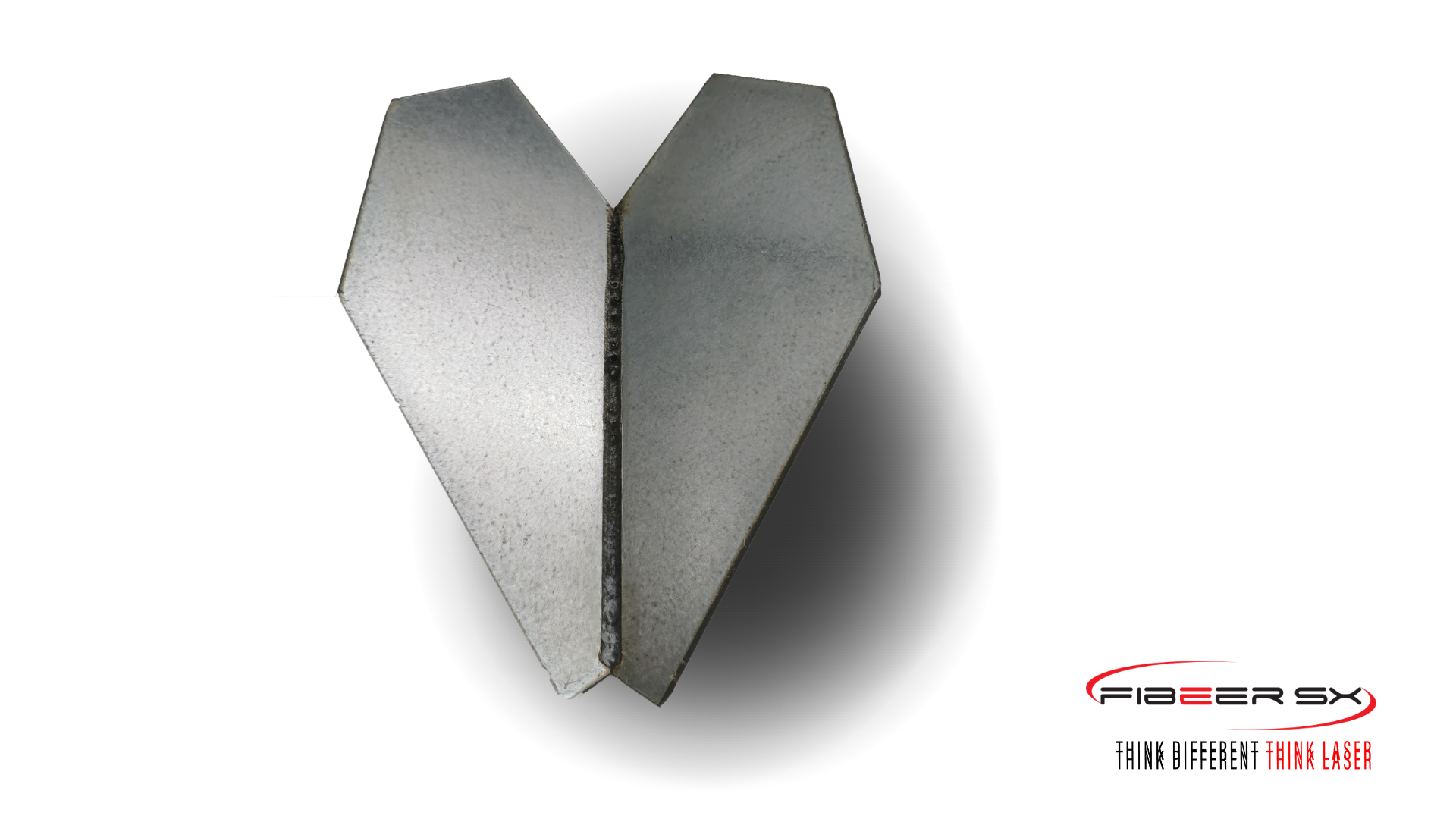

A manual laser welder is a device that uses a laser beam to join metals or other materials. The advantages of laser welding include high precision, minimal thermal effects, flexible and versatile use and high-quality welds.

Main features:

Precise controllability of the laser beam enables delicate welding work, which is important for parts with complex geometries. During work, the heat-affected zone is small, so the surrounding materials are deformed less or not at all, and require less or no post-treatment. The listed characteristics enable industrial use, for example in the automotive industry, metal industry, etc. It offers an excellent opportunity for welding body panels, exhaust systems, metal pipes, metal parts and other metal parts.

Conventional welding processes:

Conventional welding processes, such as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding, use different methods to join materials and share many similarities with laser welding. Below, I will present the traditional welding processes in more detail and compare them with laser welding.

Arc welding:

During arc welding, the heat generated by the electric arc melts the base material and welding material (if used), thus creating the joint. There are several types of arc welding, some of which are:

1.MIG/MAG (GMAW – Gas Metal Arc Welding):

In this process, a continuously fed welding wire serves as electrode and filler material. During the process, a shielding gas (inert or active) flows around the arc and weld pool to protect the molten metal from atmospheric contaminants.

Advantages: High welding speed, easy to automate.

Disadvantages: Less suitable for very thin materials, sensitive to wind due to the use of shielding gas.

2. TIG (GTAW – Gas Tungsten Arc Welding):

In this process, the tungsten electrode does not melt, but only supplies the arc. The filler must be added separately, and an inert shielding gas (usually argon) protects the molten metal.

Advantages: High quality and precision welding, good for thin materials.

Disadvantages: Slow welding speed, requires higher dexterity.

Comparison with Laser Welding:

Similarities include the formation of a melt (the base material and the welding material melt and then create a bond during cooling), although the use of welding material is not always necessary in laser welding. Another similarity may be the use of shielding gas, although this is not always necessary in the case of lasers, only in the case of certain materials.

Differences:

Heat source:

In traditional welding processes, the electric arc supplies the heat, while in laser welding, the focused laser beam supplies the heat.

Accuracy and Heat Effect:

Laser welding is extremely precise and has less heat effect, so it causes less or no distortion in the material, while traditional welding processes have a larger heat effect zone, so there is more chance of distortion.

Speed and Automation:

Laser welding is faster and easier to automate, while traditional welding processes have different speeds and automation options.

Costs:

The initial investment is higher for laser welding, but consumables and post-work costs can be lower.

Application Examples:

MIG/MAG Welding:

Suitable for welding large metal structures, such as car bodies and construction structures.

TIG Welding:

Fine and precision work such as welding stainless steel and aluminum and joining pipes and wires.

Laser welding:

Precise and beautiful seams can be created during welding, neither wire material nor shielding gas is necessary for welding, only in the case of certain raw materials.