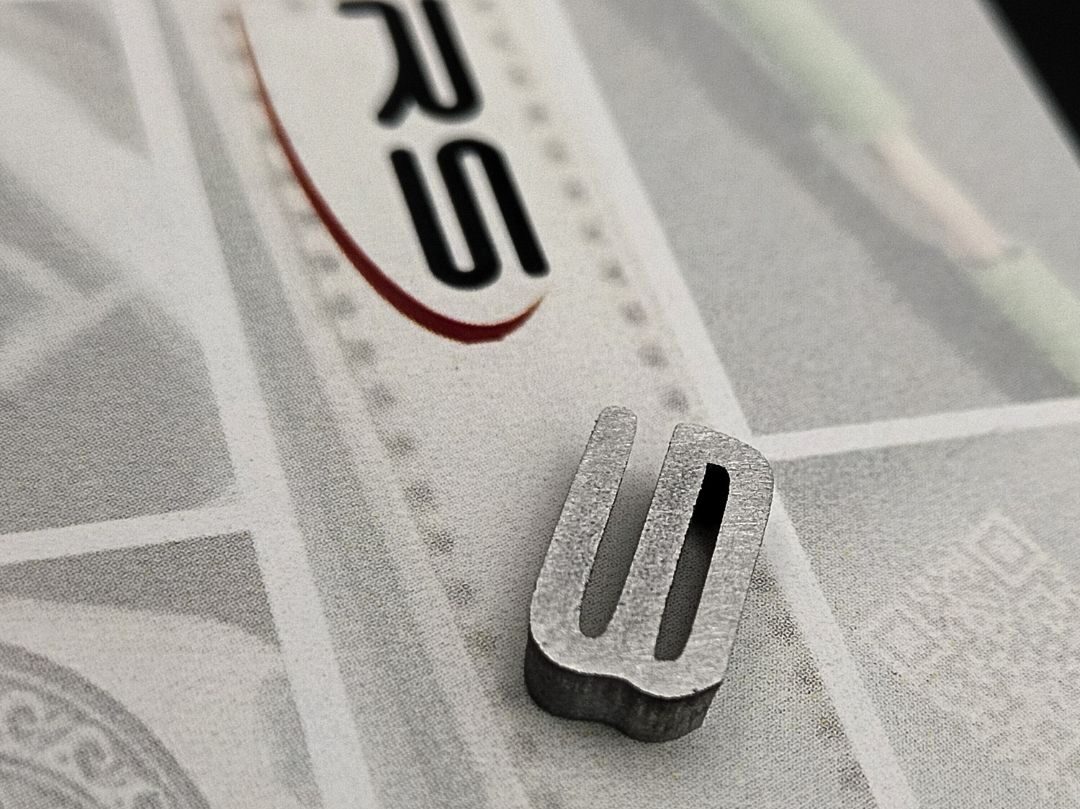

Precision laser cutting

It provides precise and versatile use, with which we can cut materials of specific shapes and sizes. We can also choose from a wide range of materials, such as metals (steel, aluminum, titanium), plastics (acrylic, polycarbonate, polypropylene, pcb), wood (plywood, MDF), composites, fabrics and textiles. The task is completely user-friendly, contact-free, and the possibility of human error can be ruled out, since the precise cutting is controlled by a computer-controlled system. It can be used especially for projects where we need a very precise cut, which affects further use. Areas of application include industrial production (automotive industry, aerospace industry, electronics), individual production and prototyping, medical industry and the electronics industry (circuit boards, housings).

Laser cutting has many advantages, including precision and accuracy, laser cutting can achieve tight tolerances of up to 0.001 inches, making it suitable for creating detailed and complex designs. It is guaranteed for versatile use, as it can cut through countless materials. Its speed is also worth highlighting, because it is faster than traditional cutting methods, which allows us to increase the efficiency of production. Quality is a primary requirement for them, and our equipment guarantees this, as it creates clean cuts with smooth edges, so there is no need for post-processing. The process is fully automated and can be repeated endlessly thanks to the software. The technology also fully complies with the ever-increasing environmental protection rules, because it minimizes the waste of raw materials thanks to efficient cutting.

Laser cutting in industries:

Automotive industry:

In the case of bodywork parts, due to its precise cutting, it is suitable for making small and large holes. Internal elements made of plastic and textile, such as; it can also be used for cutting dashboard panels and seat covers. It is a cost-effective way to test and refine the designed components, and can later be integrated into another area.

Aircraft industry:

With metal parts (aluminum, titanium), we get an accurate cut image, which is essential later for the parts to be joined. It is also suitable for cutting and shaping composite materials and trunks. The creation of precise tools and templates can also be easily cut out.

Electronics industry:

The precision laser cutting equipment can cut fine and complicated PCB without damaging the circuit boards. Precise cutting and shaping of plastic and metal housings of electronic devices or cutting and customization of display panels is also possible with the technology.

Medical technology:

It provides a precise solution for the design of small, high-precision medical devices, such as surgical instruments and implants. It is also suitable for making individual prostheses and orthopedic devices, as well as for cutting laboratory tools and accessories.

Laser cutting is therefore an essential technology in many industries, which allows manufacturers to produce various products with high precision and efficiency. With the development of technology, laser cutting becomes even more widely applicable, further increasing its importance in modern industry.

Advantages of laser cutting:

Accuracy and precision:

The laser beam is very thin and precise, allowing for meticulous and detailed cuts. Since the thermal effect zone of the laser is limited, distortion can be minimized.

Versatility:

Suitable for cutting a variety of materials including metals, plastics, wood, ceramics, glass, textiles and composite materials. The laser can not only process many materials, but also different thicknesses, from thin foils to thicker plates.

Speed and efficiency:

A faster method than mechanical cutting or sawing, thereby increasing production assistance and reducing production time. FibereSX’s software easily handles vector files (e.g. CAD/CAM), which enables automated and repetitive processes.

Quality:

Thanks to clean cutting results, post-processing is reduced or eliminated. We can minimize material loss thanks to precision, which contributes to more cost-effective production.

Cost effectiveness:

There is no need for mechanical tools that need to be replaced due to continuous wear, so we can reduce ongoing tool maintenance costs. Laser technology also contributes to the reduction of material costs, because there will be less waste of material due to the accuracy.

Safety and Environmental Protection:

The laser cutting equipment also improves the working environment, because the process involves less dust and noise. All our laser equipment provides users with energy-saving consumption, thereby contributing to environmental protection.

Flexible design:

It enables the cutting of complicated and complex shapes that cannot be solved with difficulty or at all using traditional methods. The flexible design provides the user with quick modifications, which speeds up the product development cycle.