Milling titanium involves the use of special cutting tools and techniques due to the unique properties of titanium. Titanium is known for its high strength-to-weight ratio, but it is also notoriously difficult to machine compared to other metals due to its low thermal conductivity, high chemical reactivity and tendency to harden.

In order to effectively mill titanium, several factors must be taken into account:

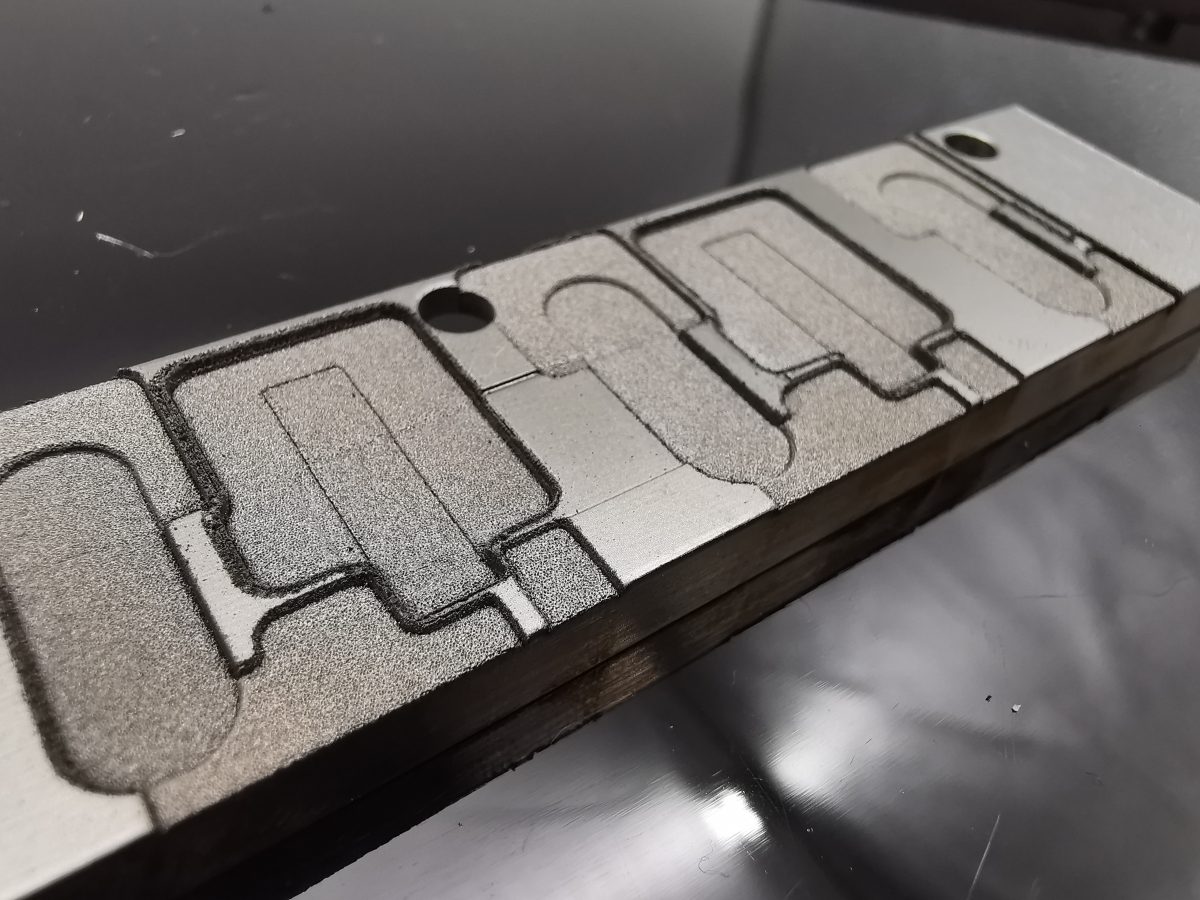

Cutting tools: High-performance carbide or ceramic cutting tools are often used to mill titanium. These tools are designed to withstand high temperatures during machining and maintain their sharpness for a longer period of time. With laser milling, you don’t need these tools, so you can easily ensure a long service life, since there is nothing to wear out.

Coolant: The use of coolant is essential to dissipate heat and prevent overheating of the tool and workpiece during titanium milling. However, conventional coolants such as water-soluble oils can react with titanium, so alternatives such as air or high-pressure coolant systems are often used. During laser milling, the heat release is concentrated, so there is no need to cool it, only to exhaust the generated dust.

Rigidity and stability: Milling titanium requires rigid setups and stable machine tools to minimize vibration, which can cause poor surface quality, tool breakage, or dimensional inaccuracies. Laser milling is a non-contact process, so you don’t have to worry about tool breakage. Thanks to the preset parameters, we can also rule out dimensional inaccuracy.

Chip removal: Titanium creates long, stringy chips during machining that can interfere with the cutting process. Adequate chip removal systems such as through-spindle coolant or chip breakers are required to maintain smooth machining. During laser milling, no chips or burrs are produced, but only dust that can be easily blown away.