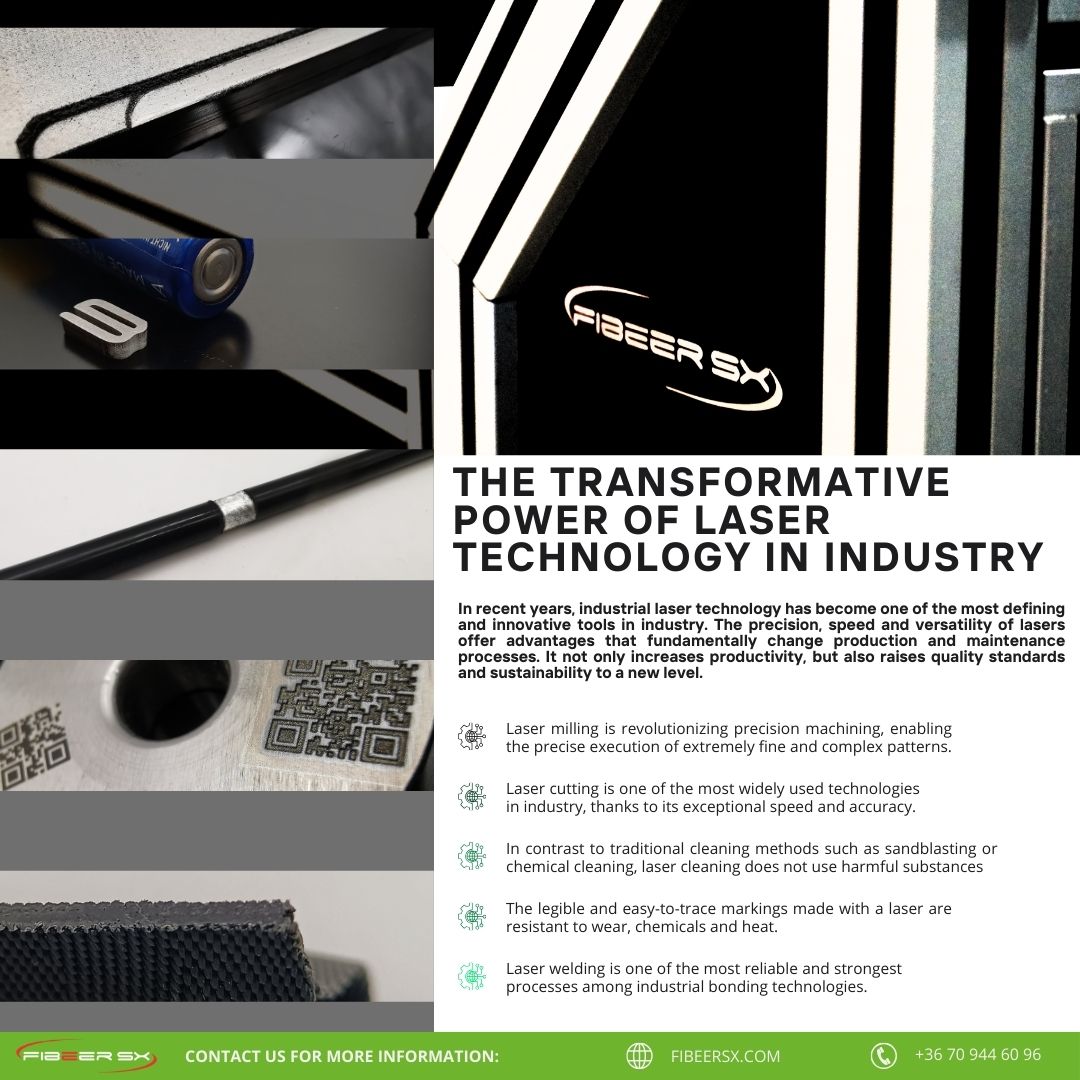

Laser cutting is one of the most widely used technologies in industry, thanks to its exceptional speed and accuracy. The process enables precise cutting of various materials with minimal material loss. It causes less deformation in the material and often does not require post-processing, which further increases efficiency.

Laser cutting is one of the most widely used technologies in industry, thanks to its exceptional speed and accuracy. The process enables precise cutting of various materials with minimal material loss. It causes less deformation in the material and often does not require post-processing, which further increases efficiency.

In contrast to traditional cleaning methods such as sandblasting or chemical cleaning, laser cleaning does not use harmful substances, thus reducing the environmental burden and health risks, which is why it is one of the most environmentally friendly and effective methods.

The legible and easy-to-trace markings made with a laser are resistant to wear, chemicals and heat. It is fast and flexible, allowing for easy marking of unique and mass-produced products without compromising the integrity of the material.

Laser welding is one of the most reliable and strongest processes among industrial bonding technologies. It can perform the task with a minimal heat effect zone, therefore it reduces deformations and cracks caused by heat, and it can be used excellently with different materials.