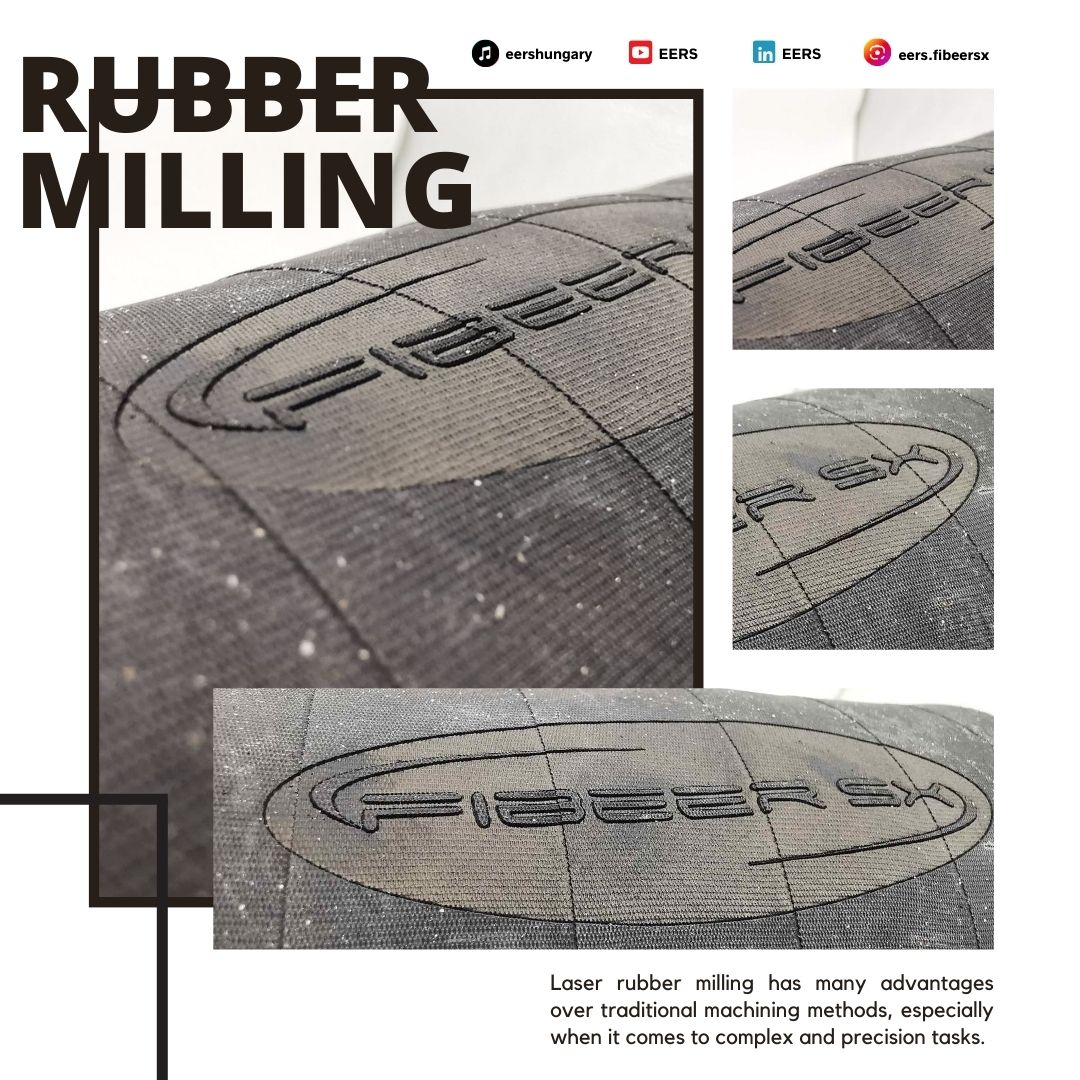

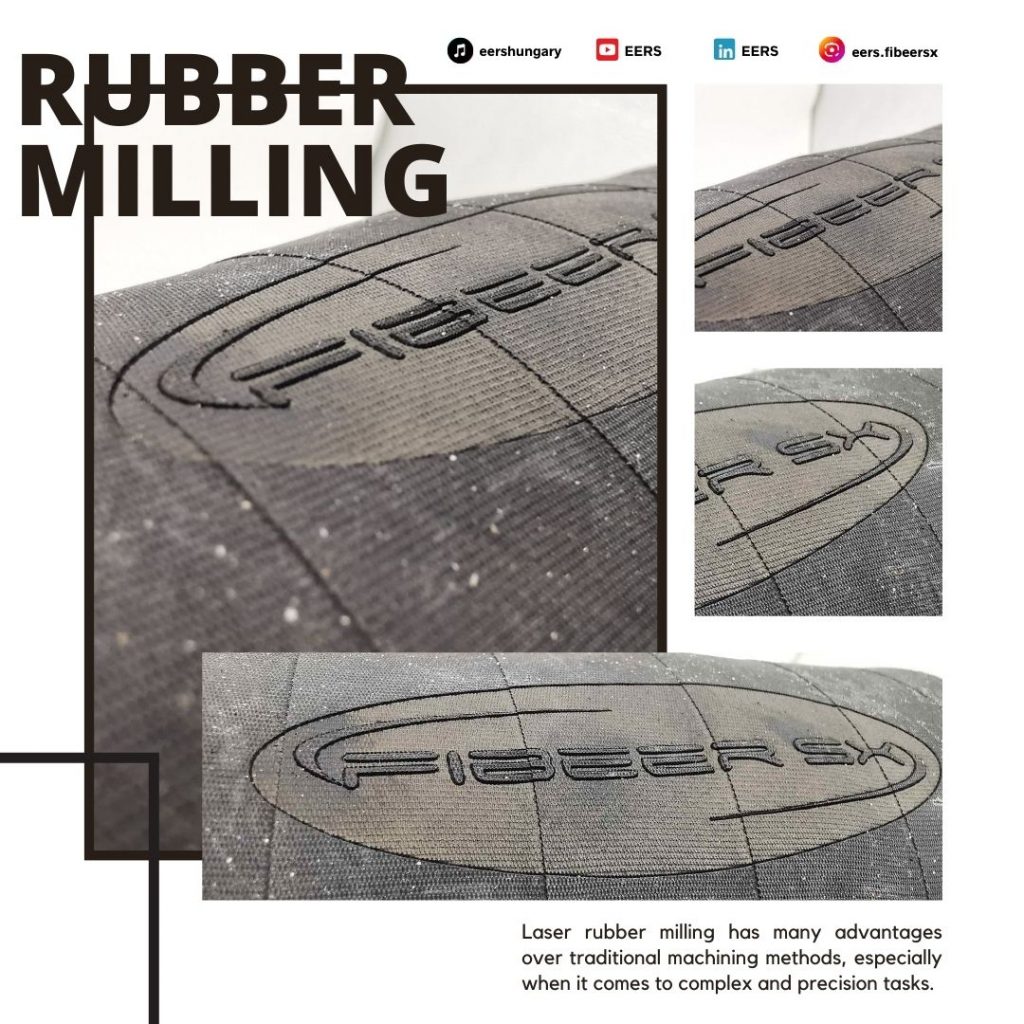

Laser rubber milling has many advantages over traditional machining methods, especially when it comes to complex and precision tasks.

High precision

The laser beam can remove material with exceptional precision, which is ideal for creating fine details and complex shapes, especially for rubber-based products.

Non-contact machining

During laser milling, there is no mechanical contact with the material, so distortion, damage or wear of the material, which often occurs with conventional tools, can be avoided.

Minimal heat effect

Laser processing involves a controlled heat effect, which helps prevent overheating or damage to the material, which is especially important for heat-sensitive rubber.

A fast and efficient process

Laser milling can be faster than traditional methods, which increases productivity, reduces production time, and results in lower costs.

Creating any complex shape

The laser allows the creation of complex shapes and patterns that are difficult to achieve with mechanical means. This is especially useful when creating unique or complex patterns on rubber surfaces.