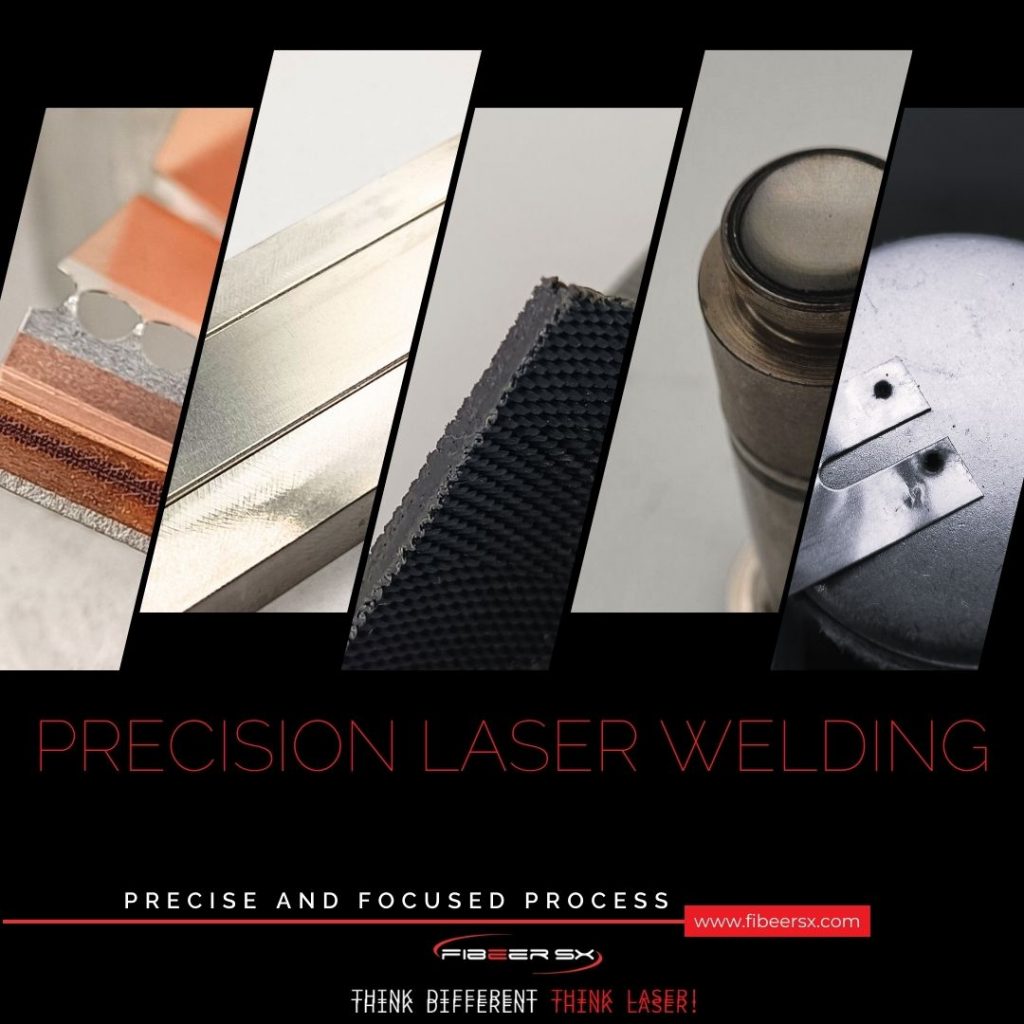

Precision laser welding equipment are special tools designed to perform fine and precise welding tasks. Precision laser welders are able to work with very tight tolerances, enabling the welding of small and sensitive parts. These devices introduce minimal heat into the material, which reduces the risk of deformation and damage to the material.

Precision laser welding systems can often be integrated into automated production lines, increasing productivity and reducing the potential for human error. They have advanced control systems that allow accurate process monitoring and adjustment. Precision laser welding equipment has revolutionized welding processes in many industries, providing high levels of precision, reliability and productivity.

Precise automated laser welding:

Automation: In this case, the welding process is performed by automated systems that use computer-controlled devices and robots.

Accuracy and repeatability: Automated systems provide extremely high accuracy and repeatability, as the programmed movements take place without human error.

Speed: Automation enables welding at higher speeds, increasing productivity and reducing lead times.

Application: Used in high-volume production such as automotive, electronic device manufacturing, and other industrial applications where precision and efficiency are key.

Costs: Higher initial investment costs are typical for the acquisition and installation of automated systems, but they pay for themselves in a short time due to long-term cost effectiveness and productivity.