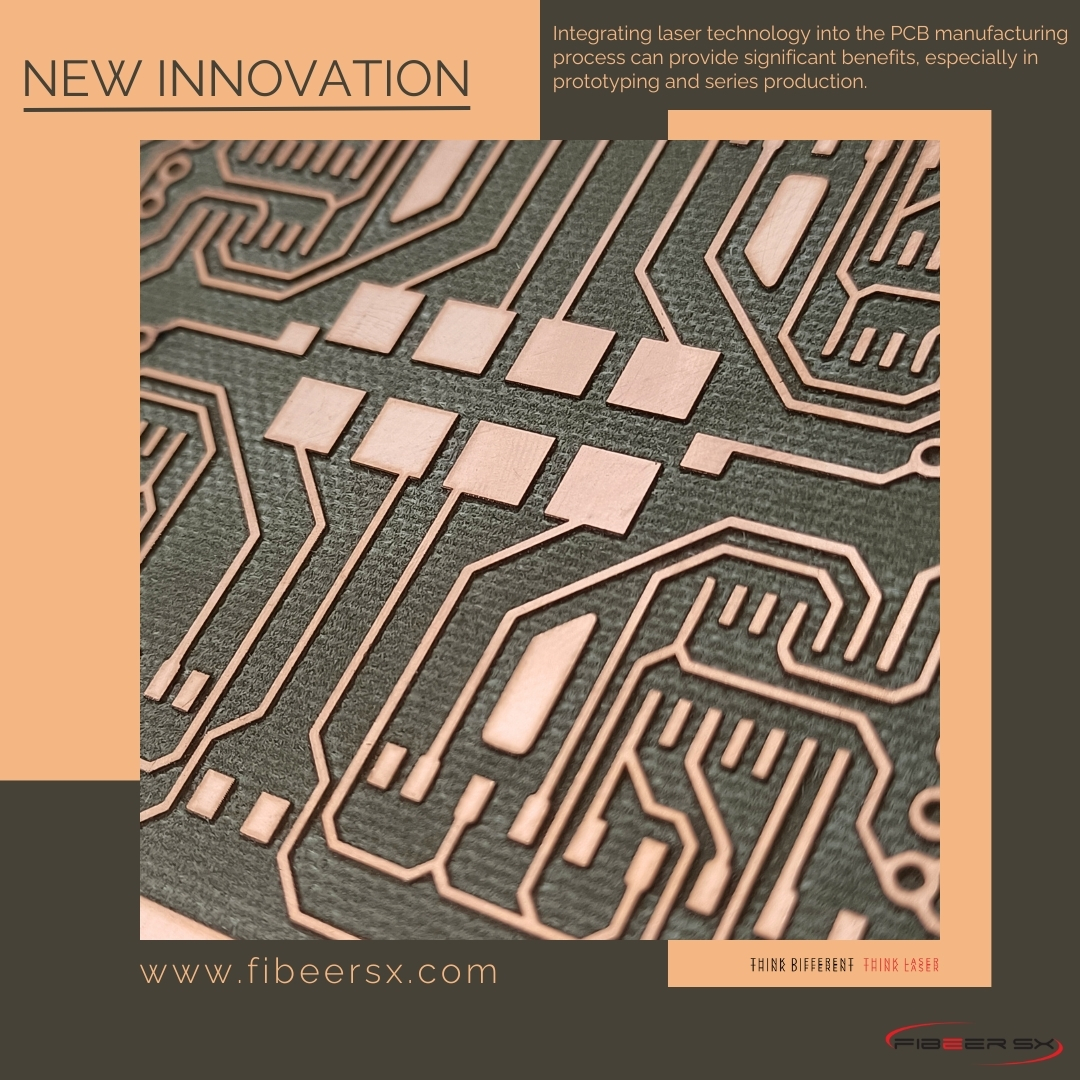

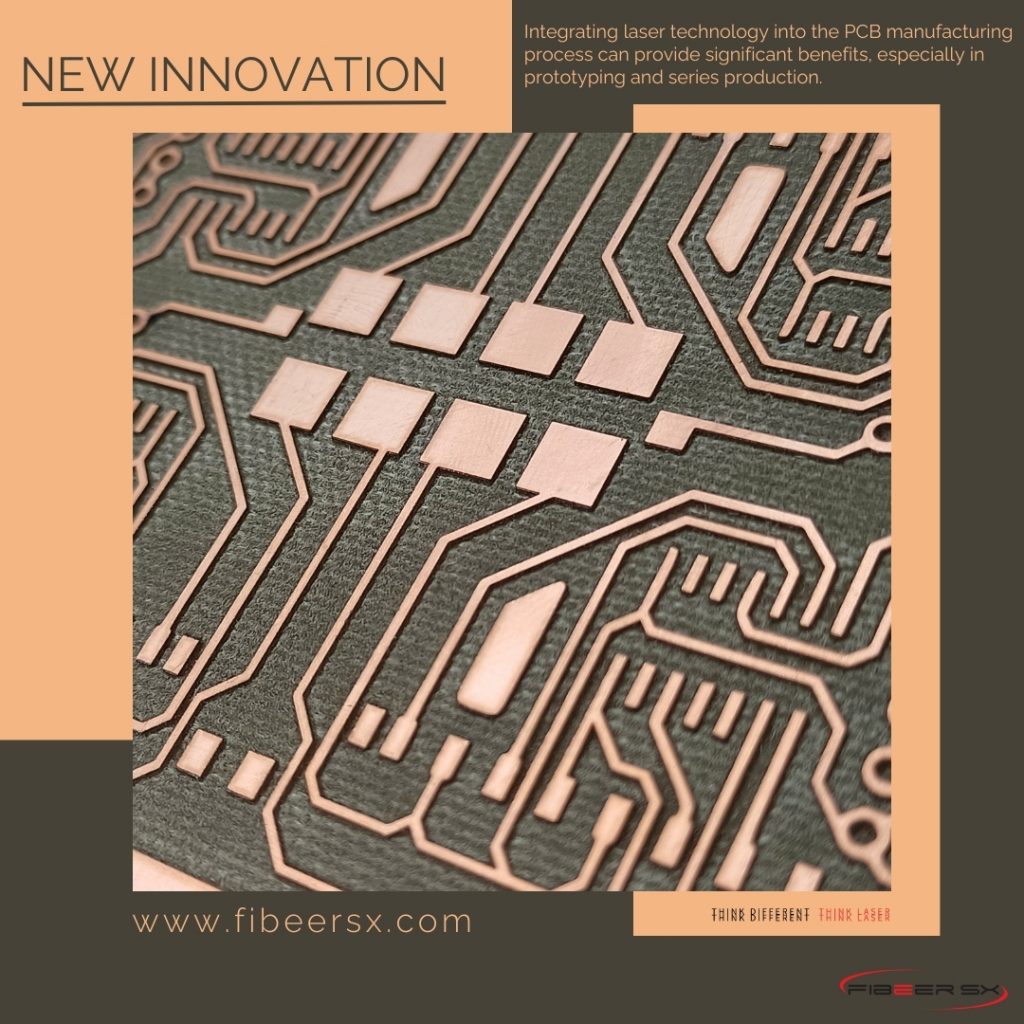

The use of laser technology for PCB (printed circuit) milling is becoming increasingly popular as it offers many advantages over traditional milling techniques. Primarily, laser milling provides exceptional precision and detail, allowing the creation of very fine patterns and lines. In addition, the process can be faster, especially for small series or unique prototypes, significantly speeding up development cycles.

Minimal material loss occurs during laser milling, which makes the technology more economical and environmentally friendly. The laser is aimed directly at the copper layer, so there is no need for chemicals or masking materials, which are essential in traditional methods.

Overall, laser technology provides greater precision, speed and efficiency while reducing waste and environmental impact, making it an ideal solution for modern PCB manufacturing.