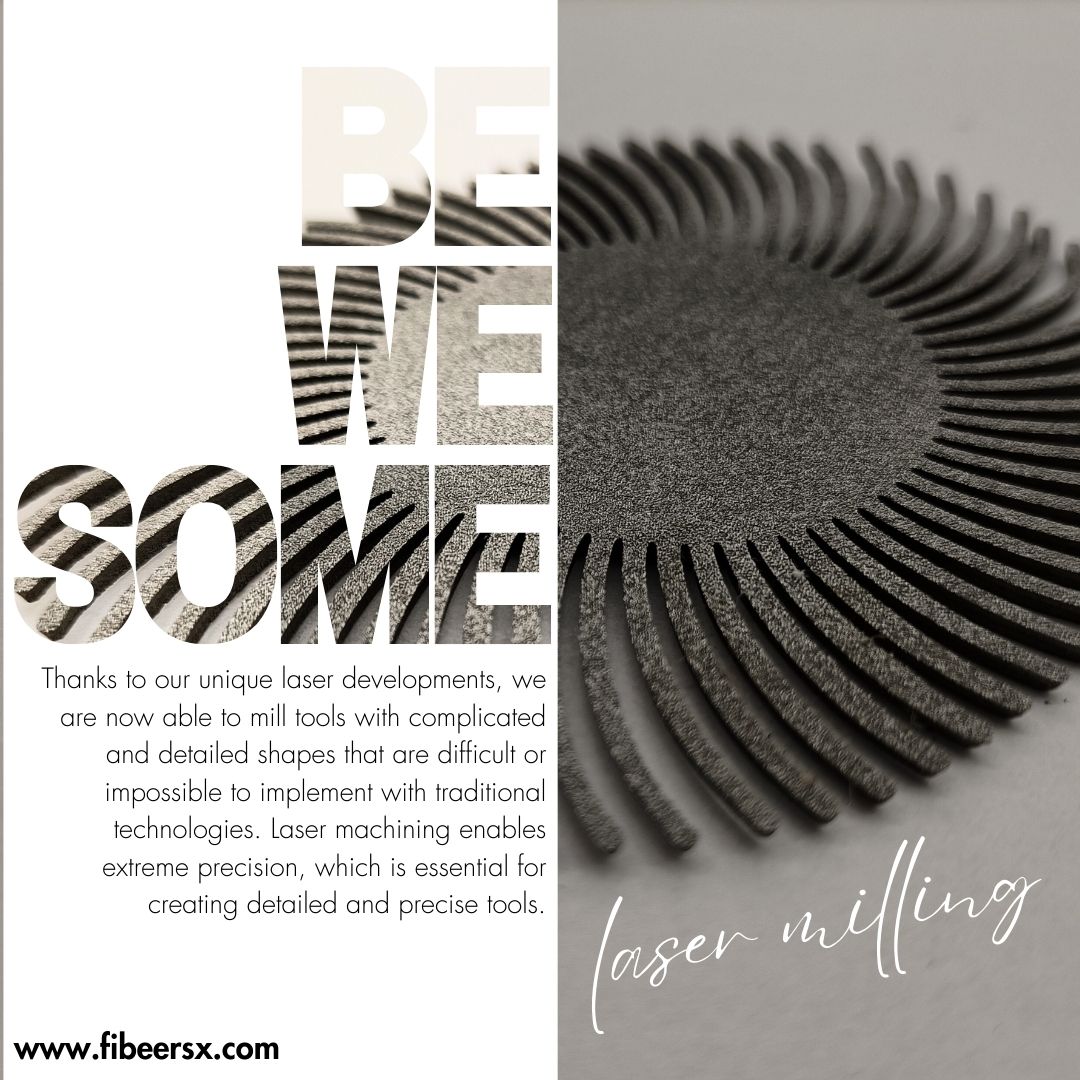

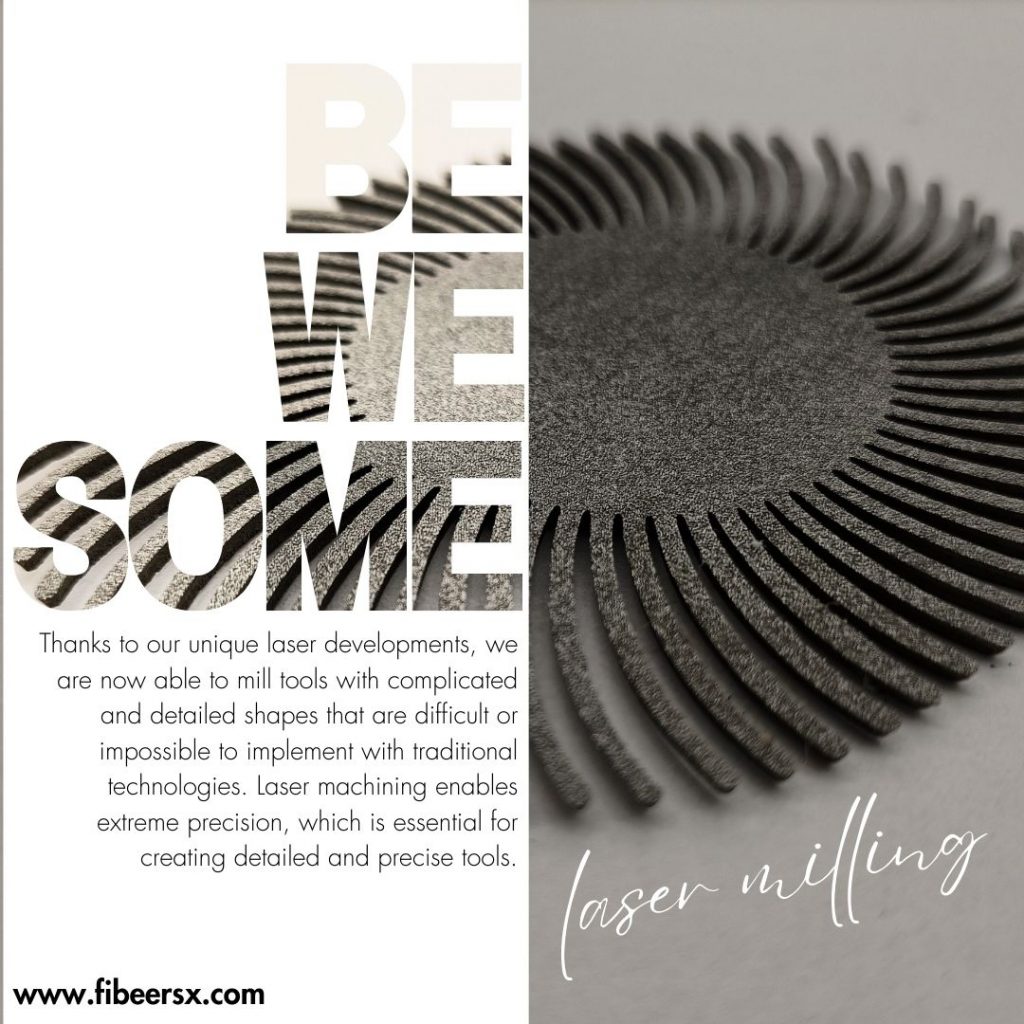

Thanks to our unique laser developments, we are now able to mill tools with complicated and detailed shapes that are difficult or impossible to implement with traditional technologies. Laser machining enables extreme precision, which is essential for creating detailed and precise tools.

High precision: Laser milling enables material removal with micrometer precision, making it excellent for creating unique and complex shapes, for example for custom tools.

Non-contact machining: Since the laser beam works without contact, mechanical wear of the tools can be avoided, which results in a longer service life and does not cause deformation of the workpiece.

Flexible material processing: Laser milling technology is suitable for processing different materials, be it metal, plastic or composite material, so it offers a wide range of applications.

Fast and efficient: Laser machining can be faster than traditional methods, which means time and cost savings in the manufacturing process.

Creation of complex patterns: The laser can easily create complex patterns and shapes that are difficult or impossible to achieve with traditional milling technologies.