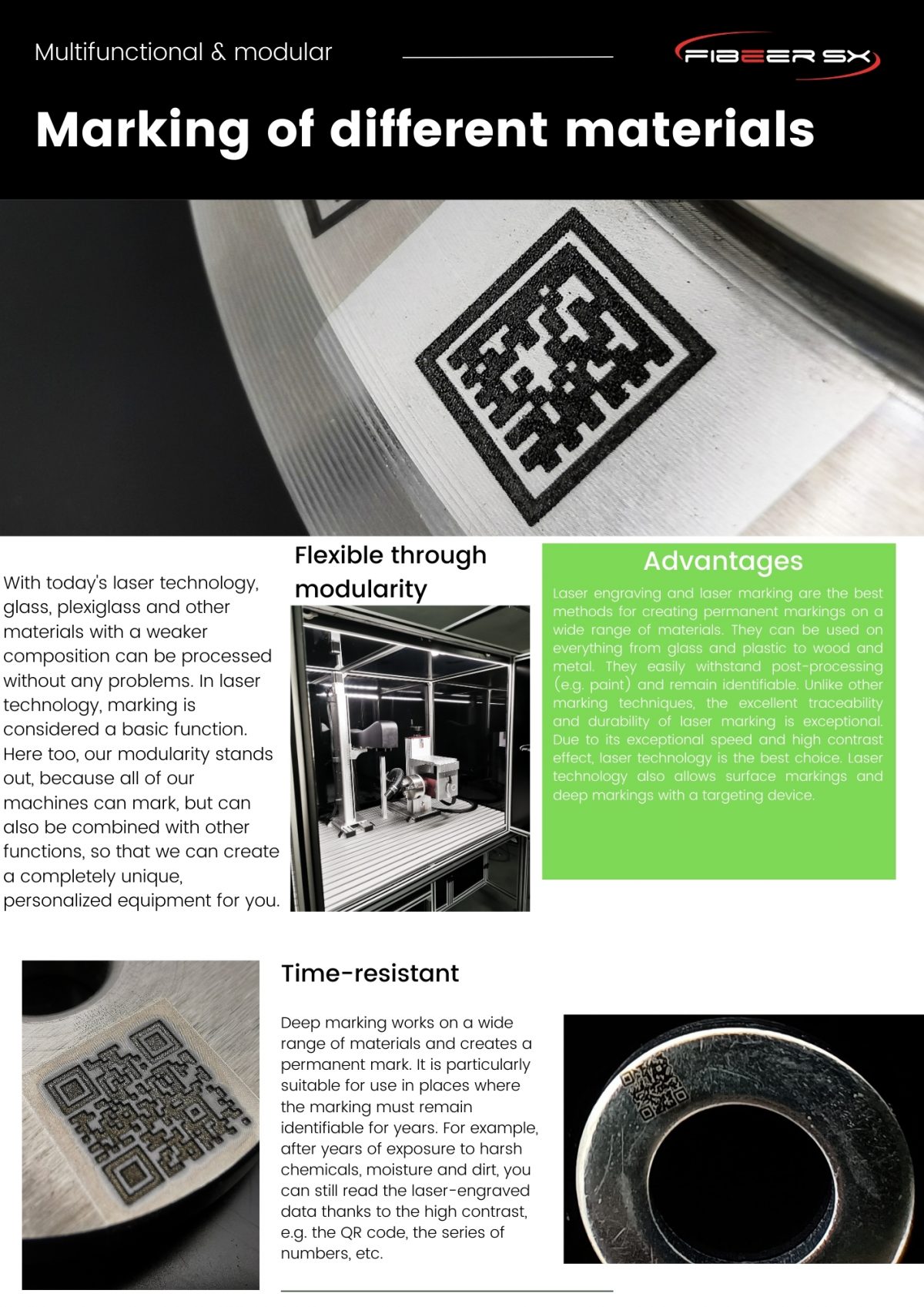

Flexible through modularity

With today’s laser technology, glass, plexiglass and other materials with a weaker composition can be processed without any problems. In laser technology, marking is considered a basic function. Here too, our modularity stands out, because all of our machines can mark, but can also be combined with other functions, so that we can create a completely unique, personalized equipment for you.

Advantages

Laser engraving and laser marking are the best methods for creating permanent markings on a wide range of materials. They can be used on everything from glass and plastic to wood and metal. They easily withstand post-processing (e.g. paint) and remain identifiable. Unlike other marking techniques, the excellent traceability and durability of laser marking is exceptional. Due to its exceptional speed and high contrast effect, laser technology is the best choice. Laser technology also allows surface markings and deep markings with a targeting device.

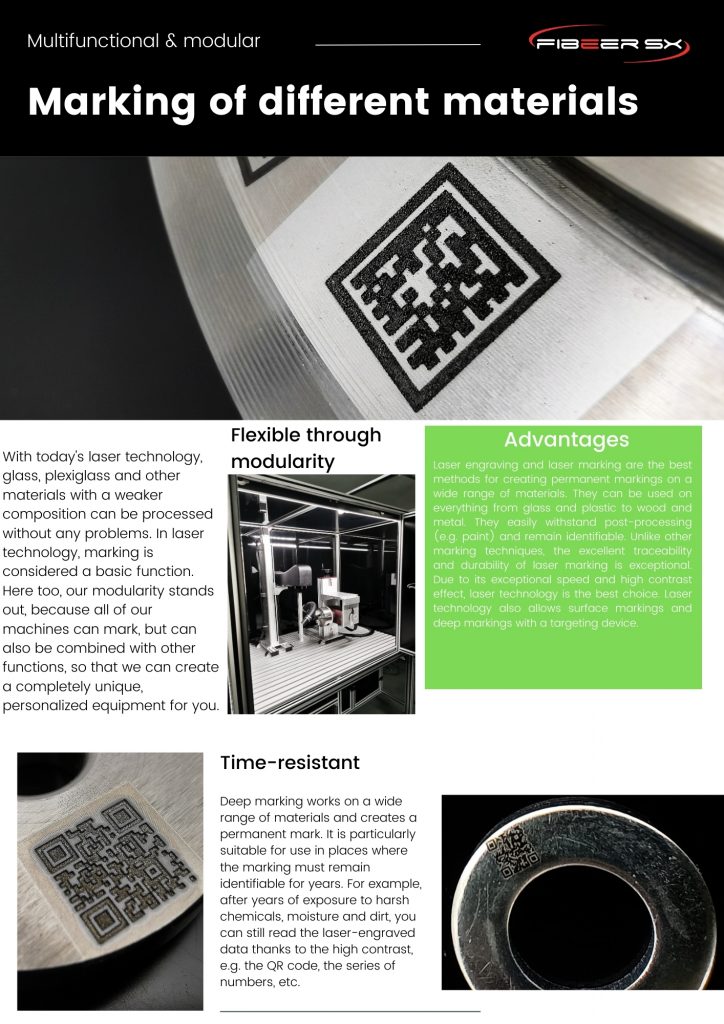

Time-resistant

Deep marking works on a wide range of materials and creates a permanent mark. It is particularly suitable for use in places where the marking must remain identifiable for years. For example, after years of exposure to harsh chemicals, moisture and dirt, you can still read the laser-engraved data thanks to the high contrast, e.g. the QR code, the series of numbers, etc.