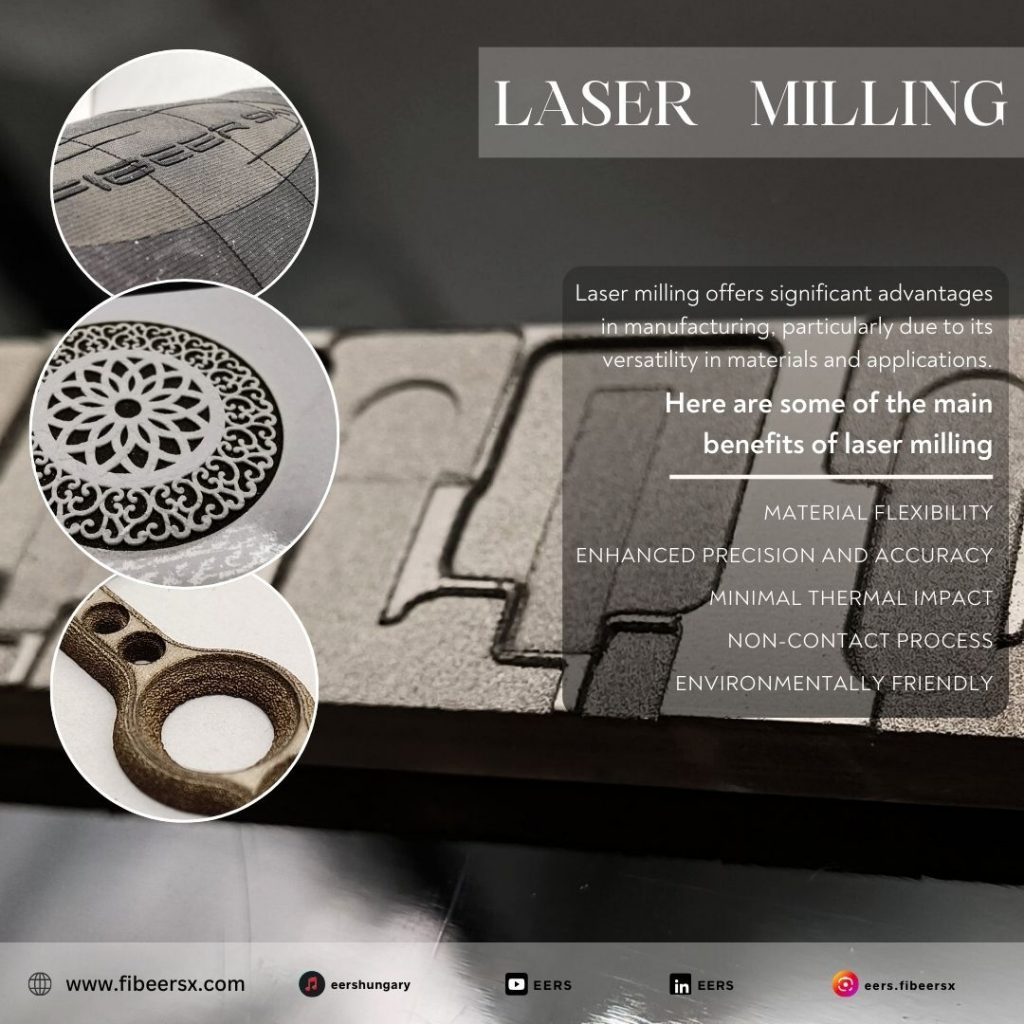

Laser milling offers significant advantages in manufacturing, particularly due to its versatility in materials and applications. Unlike traditional milling, laser milling can operate without direct contact, allowing it to handle a variety of materials, including rubber, titanium, metal alloys, and aluminum.

Here are some of the main benefits of laser milling

Material Flexibility: The precision of laser milling accommodates hard metals like titanium, soft materials like rubber, and various alloys, making it a valuable tool across industries.

Enhanced Precision and Accuracy: Laser milling achieves fine, intricate details without compromising the material’s structural integrity, making it ideal for components that require high tolerances.

Minimal Thermal Impact: Unlike conventional methods, laser milling minimizes heat-affected zones, reducing the risk of warping or deforming heat-sensitive materials.

Non-Contact Process: Since laser milling is a non-contact method, there’s no risk of tool wear or direct pressure on materials, which increases the lifespan of the laser system and ensures consistent quality.

Environmentally Friendly: Laser milling produces less waste and fewer by-products, aligning with more sustainable manufacturing practices.

Laser milling’s adaptability allows manufacturers to employ one system for multiple materials, making it a valuable investment for diverse production needs.