The cost-effectiveness of laser technology is due to several factors

Accuracy and minimal waste

Lasers work with extreme precision, which reduces material loss and the need for rework, so less material is used.

Contactless technology

Since laser processes require no mechanical contact, there is no tool wear, resulting in significant cost savings, especially in terms of maintenance and tool changes.

Energy efficiency

Laser processes use much less energy compared to traditional machining techniques.

Multifunctional tools

Modern laser machines are able to perform multiple tasks at the same time, which reduces the number of devices and the costs of machine investments.

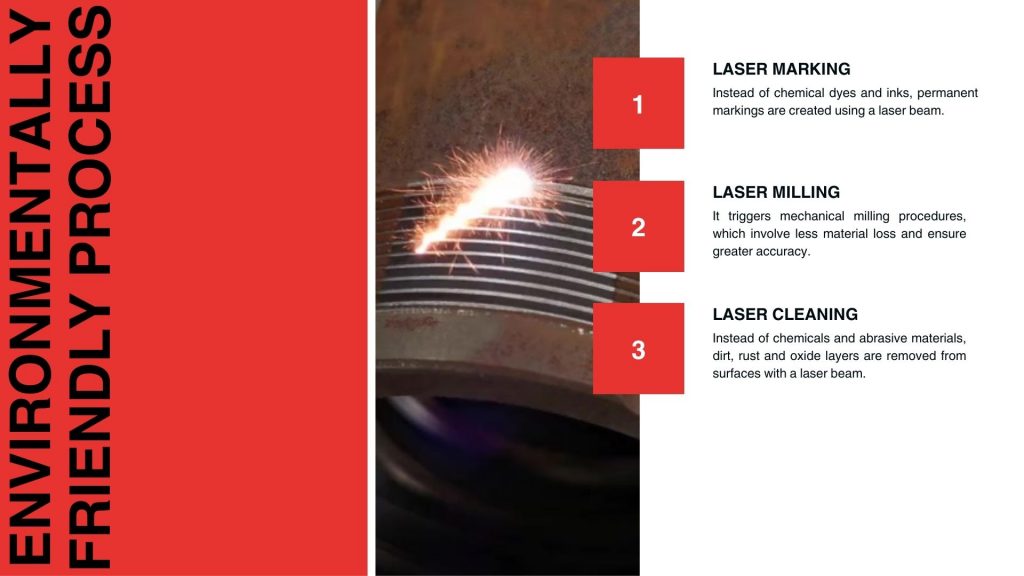

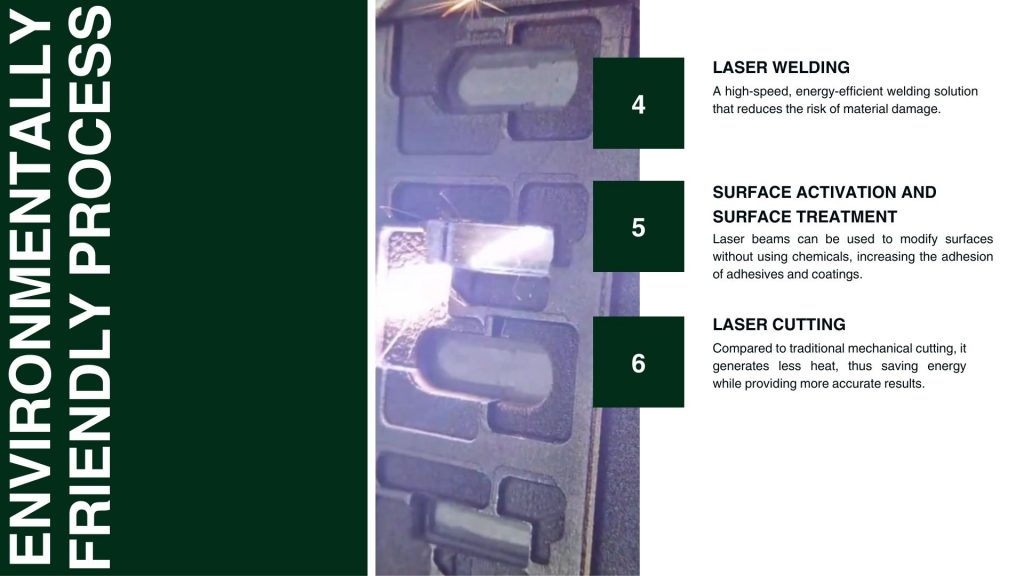

Environmentally friendly process

Laser technology is truly one of the most environmentally friendly industrial solutions, as it can process materials chemical-free, contact-free and with high precision in many industrial processes. All of the following laser procedures are environmentally friendly, as they do not require chemicals, use less energy, and produce minimal waste.

Laser marking

Instead of chemical dyes and inks, permanent markings are created using a laser beam.

Laser milling

It triggers mechanical milling procedures, which involve less material loss and ensure greater accuracy.

Laser cleaning

Instead of chemicals and abrasive materials, dirt, rust and oxide layers are removed from surfaces with a laser beam.

Laser cutting

Compared to traditional mechanical cutting, it generates less heat, thus saving energy while providing more accurate results.

Laser welding

A high-speed, energy-efficient welding solution that reduces the risk of material damage.

Surface activation and surface treatment

Laser beams can be used to modify surfaces without using chemicals, increasing the adhesion of adhesives and coatings.

The advantages of all processes include the absence of chemicals, energy efficiency, and minimal material loss, which reduces the environmental impact, so laser technologies offer truly green solutions in industrial processes.