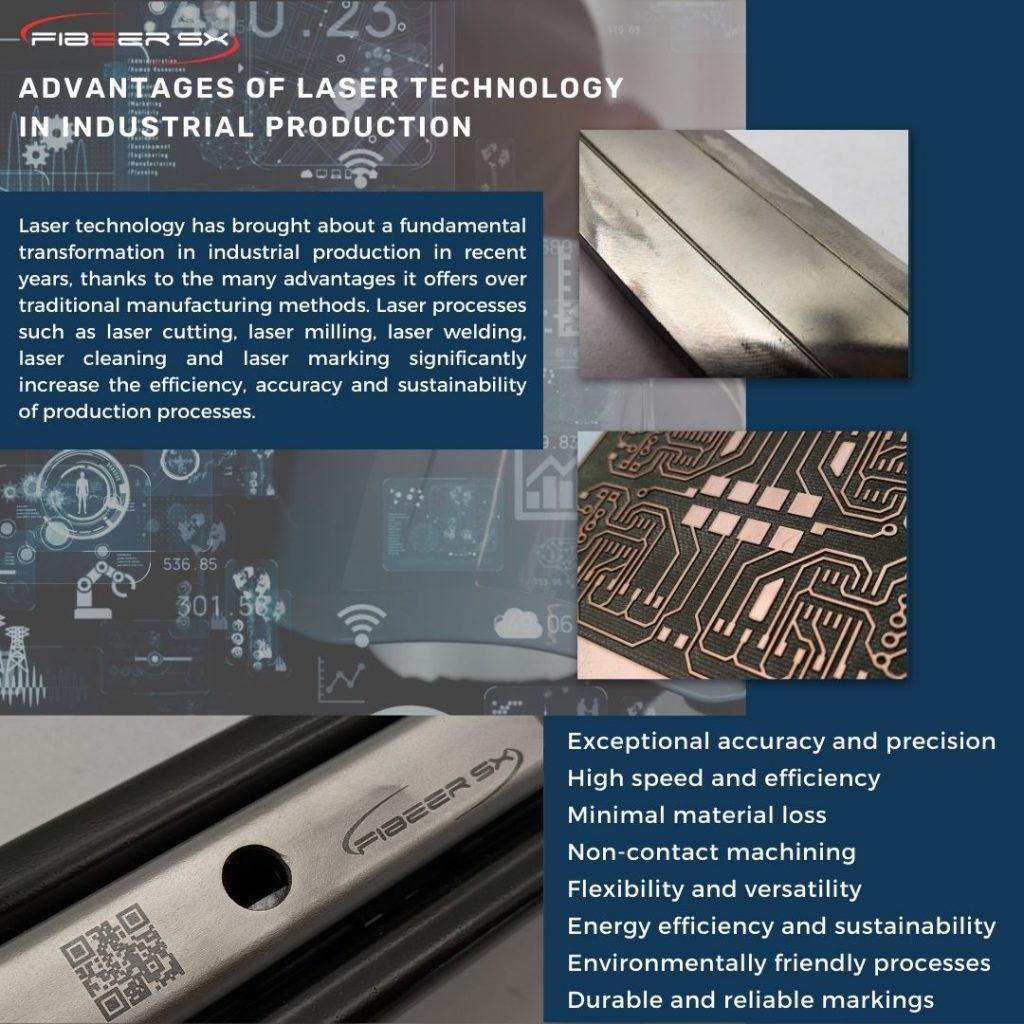

Laser technology has brought about a fundamental transformation in industrial production in recent years, thanks to the many advantages it offers over traditional manufacturing methods. Laser processes such as laser cutting, laser milling, laser welding, laser cleaning and laser marking significantly increase the efficiency, accuracy and sustainability of production processes.

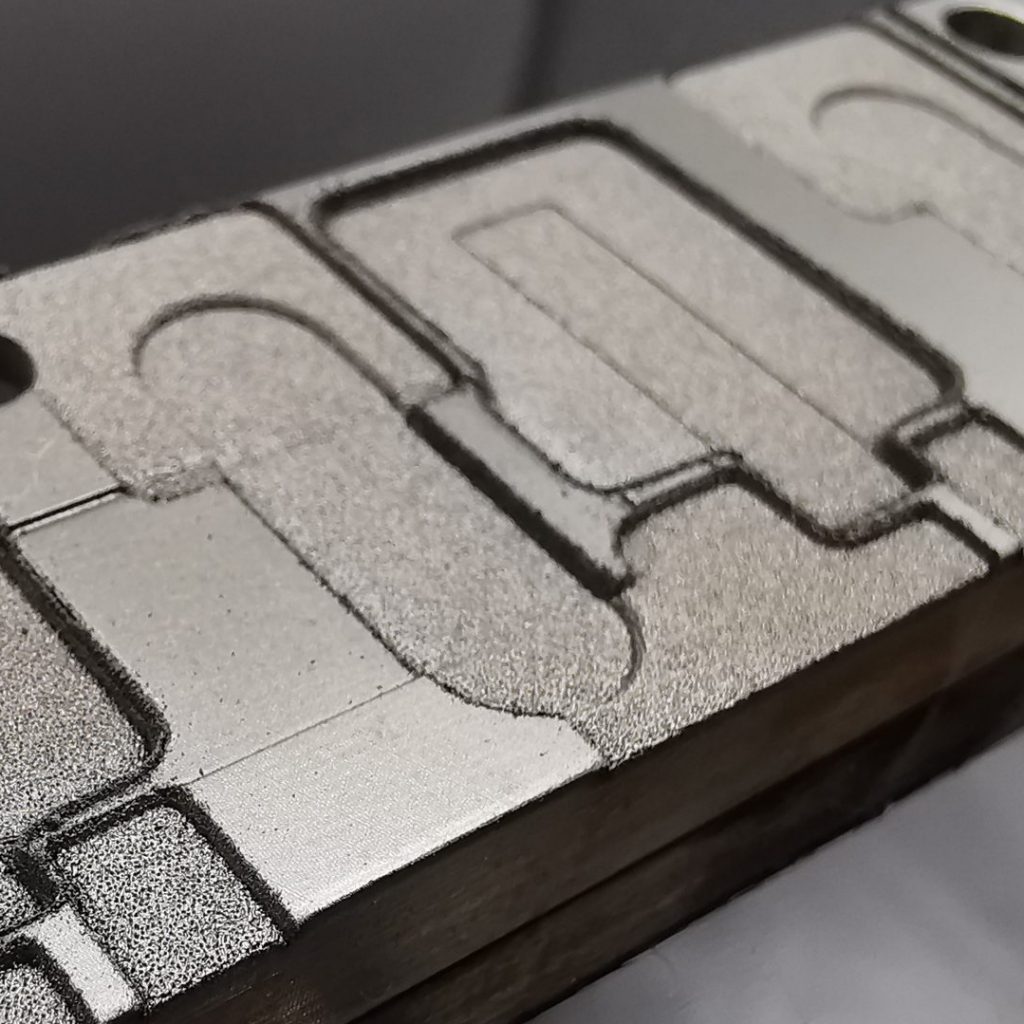

Exceptional precision and accuracy

One of the biggest advantages of laser technology is its extreme accuracy. Laser beams are capable of producing micrometer-sized details, which is especially useful for machining fine, intricate patterns and parts.

High speed and efficiency

Laser technologies stand out for their speed. Laser cutting and laser milling, for example, enable fast and efficient material processing, which significantly reduces the production cycle time. Also in the case of laser welding, laser fusion is faster and more accurate than traditional welding methods, thus increasing production efficiency.

Minimal material loss

During laser technology, material removal is extremely precise, resulting in minimal material loss. This not only reduces production costs, but also contributes to more sustainable production processes, as less waste is generated.

Non-contact machining

Lasers enable non-contact machining, which reduces the risk of mechanical damage to materials. This is particularly beneficial for sensitive or difficult-to-machine materials such as thin sheet metal, composites, and plastics. The non-contact process also reduces tool wear, which further increases the efficiency and reliability of the processes.

Flexibility and versatility

Laser technology can be used extremely flexibly in different materials and production processes. And laser marking and laser cleaning offer the opportunity to customize and optimize production processes without having to use different tools or tools.

Energy efficiency and sustainability

The concentrated energy of the lasers is directed exactly where it is needed, resulting in minimal energy loss. Efficiency contributes to the sustainability of production processes, reducing the environmental footprint of production.

Environmentally friendly processes

Laser machining methods, such as laser cleaning, offer an environmentally friendly alternative to traditional cleaning and surface treatment processes that often require chemicals or abrasives. Chemicals are not needed during laser cleaning, so less hazardous waste is generated and the working environment becomes safer.

Durable and reliable markings

Laser marking technology provides durable and accurate markings that are resistant to wear, chemicals and heat.