Thanks to the precision, speed and versatility of modern laser technology, it offers effective solutions in many areas, be it industrial, medical or scientific applications.

Thanks to the precision, speed and versatility of modern laser technology, it offers effective solutions in many areas, be it industrial, medical or scientific applications.

Technology:

- welding

- marking

- cleaning

- cutting

- milling

- surfacetreatment

Thanks to the precision, speed and versatility of modern laser technology, it offers effective solutions in many areas, be it industrial, medical or scientific applications.

Thanks to the precision, speed and versatility of modern laser technology, it offers effective solutions in many areas, be it industrial, medical or scientific applications.

Technology:

Custom laser equipment can be tailored to specific applications, providing customized solutions that may not be possible with catalog equipment. This customization results in better performance and efficiency, and is also suitable for performing very unique and difficult tasks.

Unique features or capabilities provide versatile use for users.

Tailoring laser equipment to specific applications improves performance metrics such as accuracy, speed, and reliability.

Customized solutions are more efficient, require less maintenance and can last longer, reducing overall operating costs.

Customized laser equipment can be designed with sustainability in mind, incorporating energy-efficient components or reducing waste from manufacturing processes. This corresponds to the growing demand for environmentally friendly solutions in many industries.

The precision automatic laser cleaner is an advanced technological device that uses laser beams to remove dirt, oxidation and other unwanted materials from various surfaces. This cleaning method is highly efficient and accurate, and is used in many industries such as manufacturing, automotive and electronics.

High Precision: Laser cleaners are able to clean very fine details without damaging the surface to be cleaned.

Automation: Automated systems enable continuous operation without human intervention, increasing efficiency and reducing labor costs.

Environmentally friendly: Laser cleaning does not require chemicals or solvents, so it is an environmentally friendly alternative to traditional cleaning methods.

Minimal Maintenance: Laser systems have few moving parts, which means low maintenance.

Efficiency: Fast and thorough cleaning that can cover large surfaces in a short time.

Safety: During laser cleaning, no dangerous substances are released into the air, which creates a safer working environment.

Versatility: Can be used on a variety of materials including metals, plastics, composites and glass.

Accuracy: The laser can remove precise layers of the surface, which is especially useful when cleaning monuments or sensitive parts.

1. Understanding your vision

Initial consultation: We start with an in-depth discussion to understand your vision for project implementation.

2. Defining the scope

Project Requirements: List functional and non-functional requirements.

3. Planning

Let’s plan together what will be the best solution for you.

During the design, we take into account the creation of a user-friendly interface.

4. Installation

We also help with installation and training, for which we agree on the influencing factors in advance.

5. Maintenance and Support

We maintain our equipment in a preventive manner so that there are no breakdowns and we can also increase the lifespan of the machine.

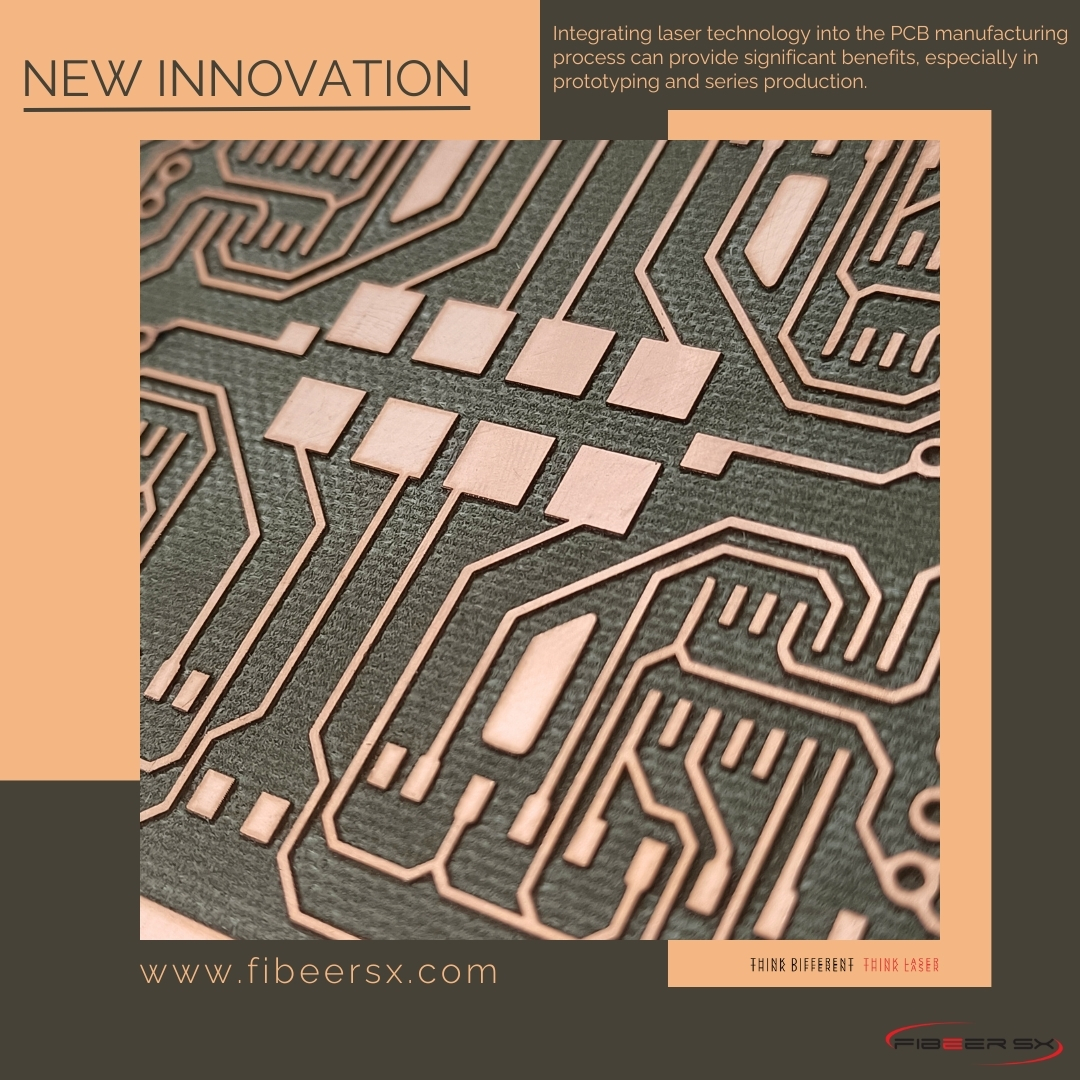

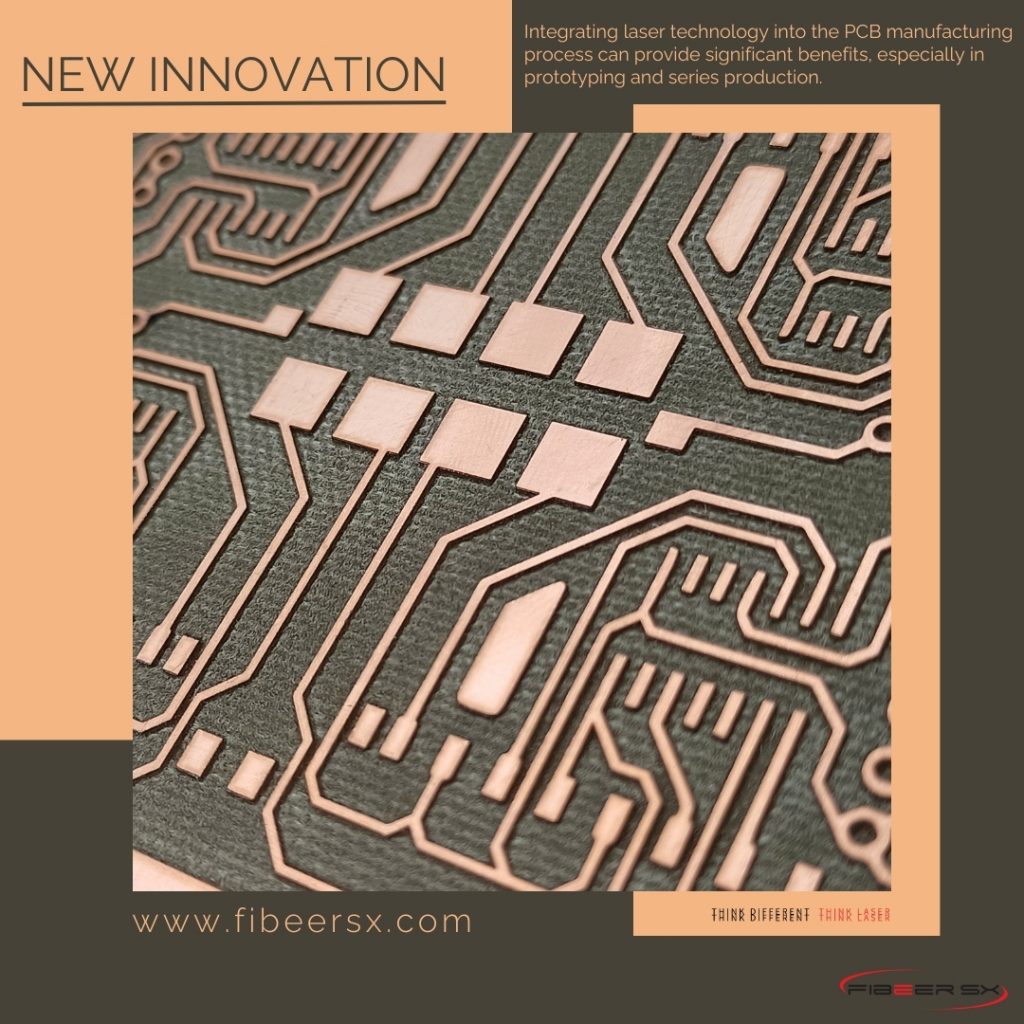

Minimal material loss occurs during laser milling, which makes the technology more economical and environmentally friendly. The laser is aimed directly at the copper layer, so there is no need for chemicals or masking materials, which are essential in traditional methods.

Overall, laser technology provides greater precision, speed and efficiency while reducing waste and environmental impact, making it an ideal solution for modern PCB manufacturing.

Automotive cleaning refers to the collection of various cleaning methods and techniques used in the manufacture, maintenance and repair of vehicles. These cleaning procedures are not only limited to the exterior and interior cleaning of cars, but also to the cleaning of machinery and equipment used in manufacturing processes. Laser cleaning is an efficient and environmentally friendly solution used in the automotive industry for the surface treatment and cleaning of vehicle parts. Laser technology allows the removal of paint layers, rust, oil stains, dirt and other deposits without damaging or scratching the base material.

Laser cleaning does not require the use of chemicals or other pollutants when removing dirt, so we can reduce environmental pollution and the treatment of hazardous waste. Laser cleaning produces a minimal amount of waste, and in most cases only the cleaned dirt remains. Furthermore, we can reduce the need for consumables (chemicals, brushes, cloths, etc.).

Thanks to the precision of the laser, we can minimize the risk of damage to the parts. Since the energy of the laser can be regulated, it adapts to different materials and surfaces. Many materials and impurities can be removed with this process, e.g. rust, glue, resin, lubricants, etc. Suitable for cleaning various materials and surfaces, including metal, plastic, glass and other materials.

From a hygienic point of view, the laser creates a clean environment, which is an important factor in the production of car parts or during vehicle production. Also, it does not cause mechanical damage or wear on the surface, which is why it is ideal for cleaning sensitive or complex parts.

Paint and coating removal:

Removal of old paint layers, oxidation and corrosion from bodywork and other metal parts. It is also suitable for the preparation of new painting and coating processes.

Cleaning the engine and other parts:

Removal of oil and grease stains from engine parts. Surface preparation of parts for repair or assembly processes.

In the automotive industry, laser cleaning is used in a wide variety of applications, such as cleaning engine parts, brake systems, transmissions and other components, as well as refinishing or refinishing car bodies. This technology can contribute to improving the efficiency and quality of production processes in the automotive industry.

The continuous development of laser technology creates many opportunities for the glass industry as well. Laser solutions used in glass production enable greater precision, efficiency and flexibility during production processes.

Laser technology can be widely used in various processes of glass production, for example;

Cutting: Laser cutting and machining is a very precise and efficient method of cutting and shaping glass sheets and other glass products to size. This allows for the creation of intricate patterns and shapes without having to remove large amounts of material

Marking: Laser technology enables precise marking of glass surfaces. for example marking logos, texts or individual designs.

Advantages:

Preventive maintenance is extremely important for technologies such as our company deals with, for example laser equipment. This is important because it helps to minimize possible breakdowns and downtime, and preserves the efficiency and lifespan of the equipment.

Preventive maintenance activities may include regular cleaning, lubrication, calibration, and inspection, as well as periodic replacement of components, even if they appear to be in working order. These activities help prevent the cumulative effects of minor problems before they lead to a more serious failure or outage.

1. Increases availability: With the help of periodic maintenance, unexpected breakdowns can be minimized, thus increasing equipment availability and uptime.

2. Reduces costs: Preventive maintenance can help avoid expensive repairs and downtime, thereby reducing operating costs and potential lost revenue.

3. Maintains productivity: Regular maintenance ensures that equipment is operating optimally, thereby maintaining productivity and quality.

4. Extends Life: Preventive maintenance helps extend the life of equipment, maximizing its value and return.

5. Increases safety: Regular inspections and maintenance activities can help identify and correct safety hazards, which improves workplace safety.

Overall, preventive maintenance is essential to ensure the efficient operation of laser equipment and other complex technologies and contributes to long-term business success.

After submit, you will receive the catalog via e-mail!