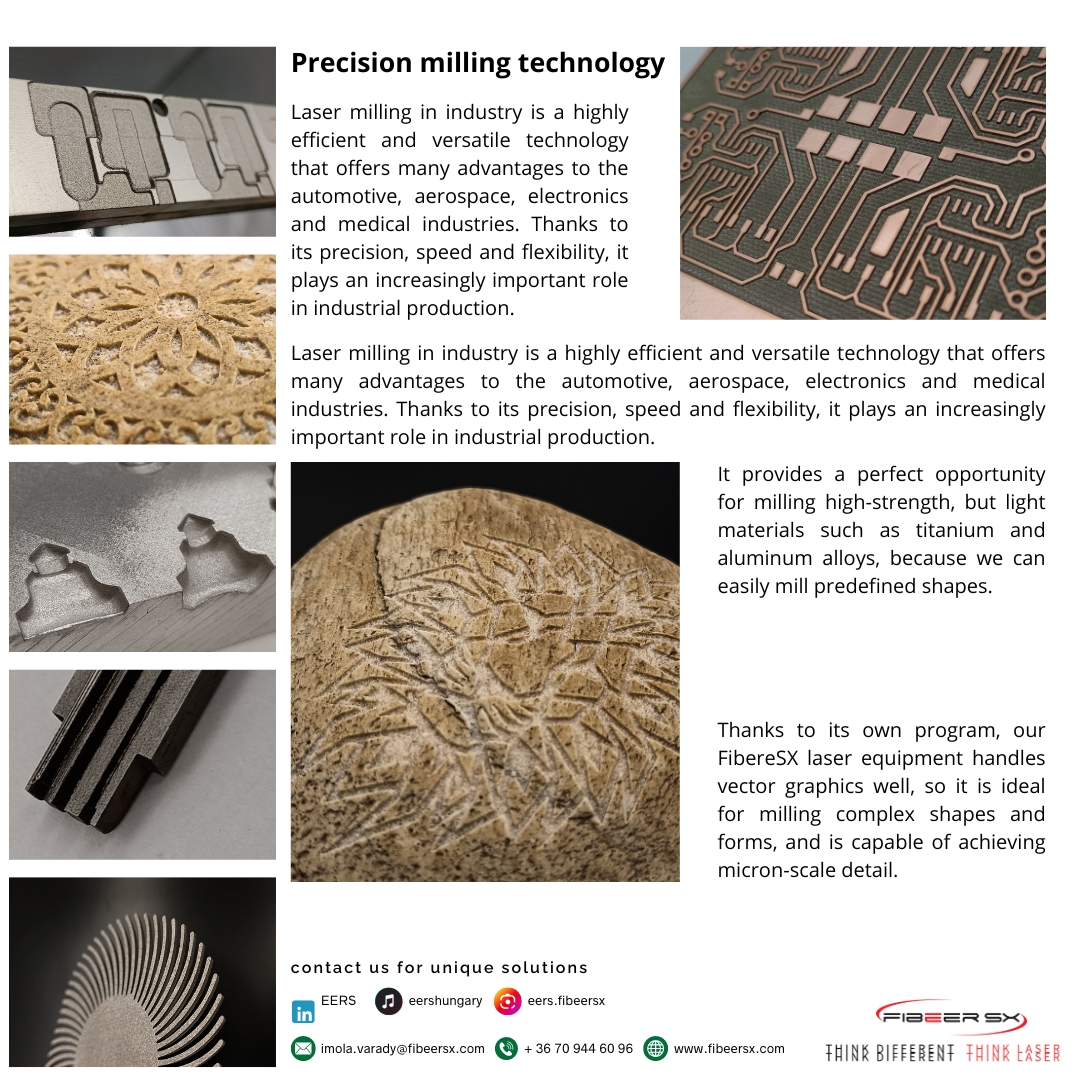

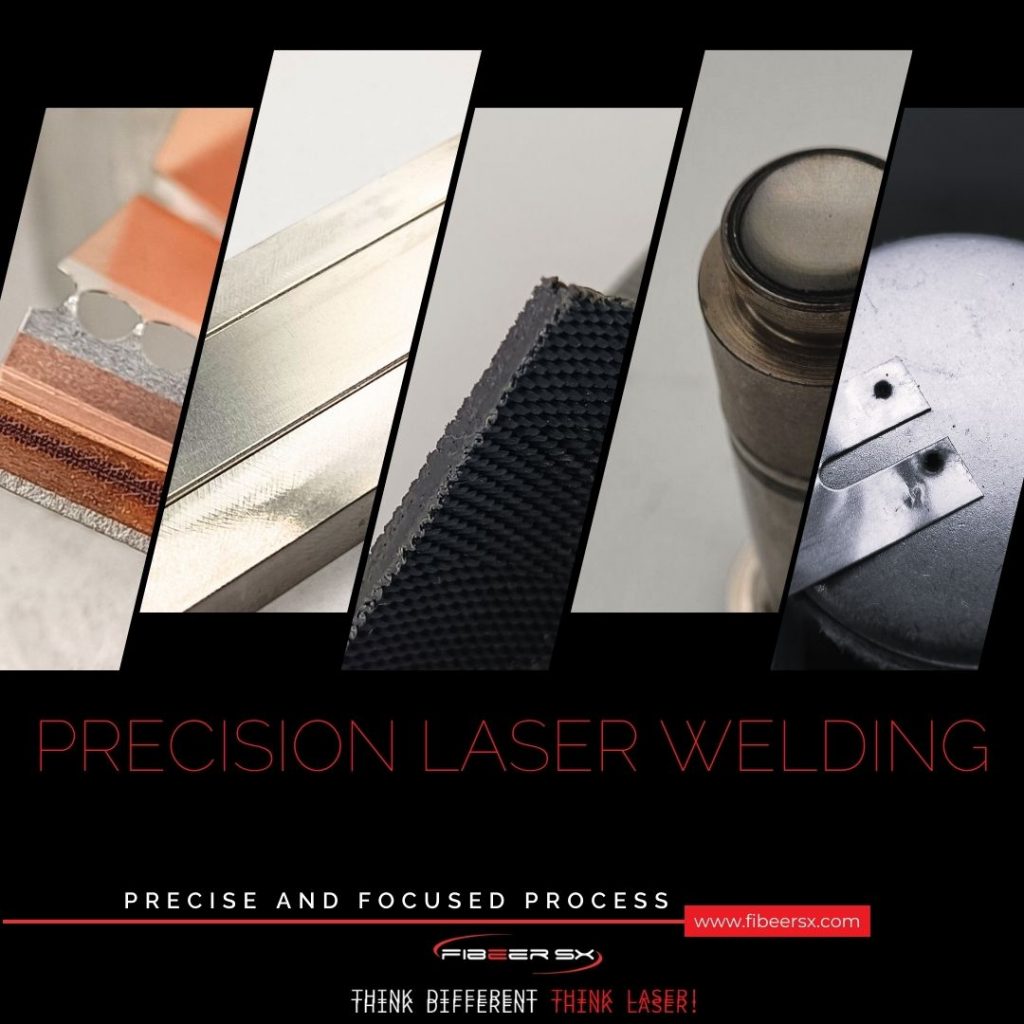

Laser milling in industry is a highly efficient and versatile technology that offers many advantages to the automotive, aerospace, electronics and medical industries. Thanks to its precision, speed and flexibility, it plays an increasingly important role in industrial production.

Laser milling in industry is a highly efficient and versatile technology that offers many advantages to the automotive, aerospace, electronics and medical industries. Thanks to its precision, speed and flexibility, it plays an increasingly important role in industrial production.

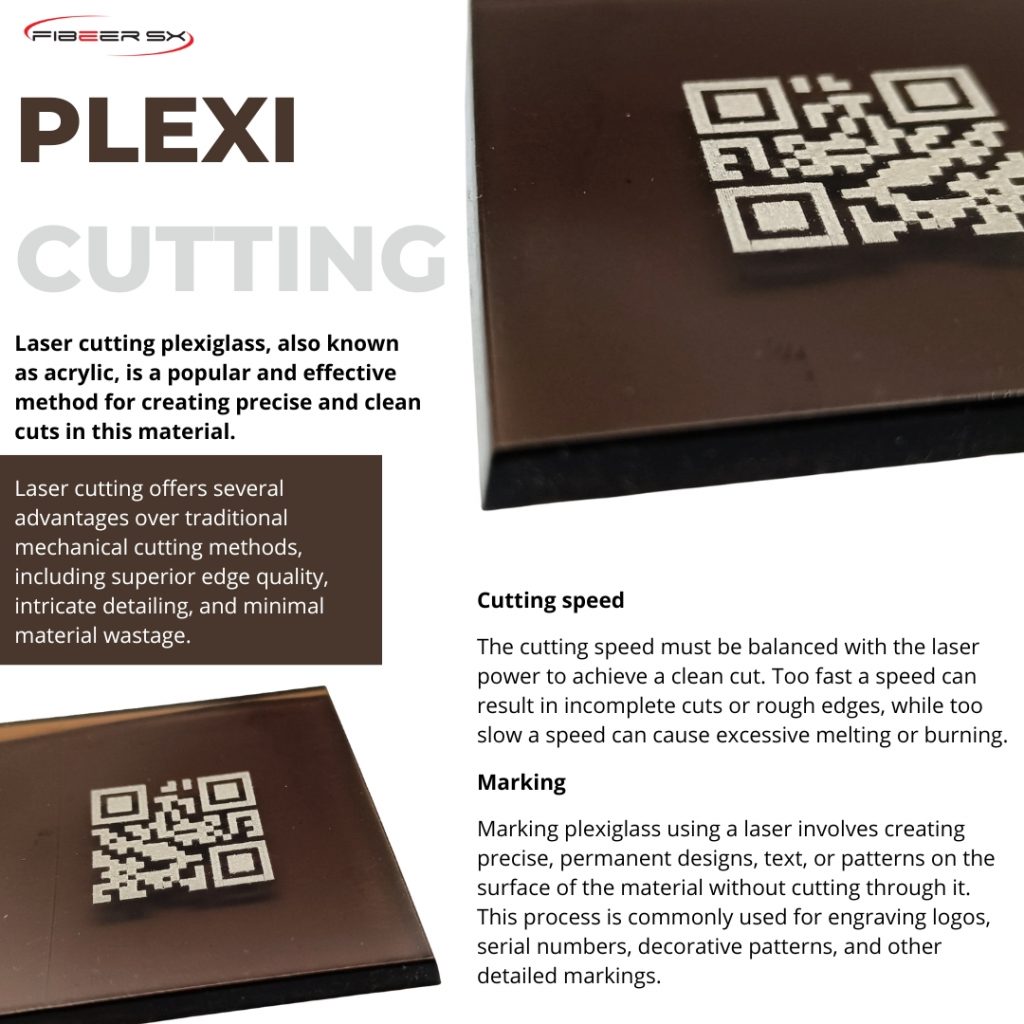

It provides a perfect opportunity for milling high-strength, but light materials such as titanium and aluminum alloys, because we can easily mill predefined shapes.

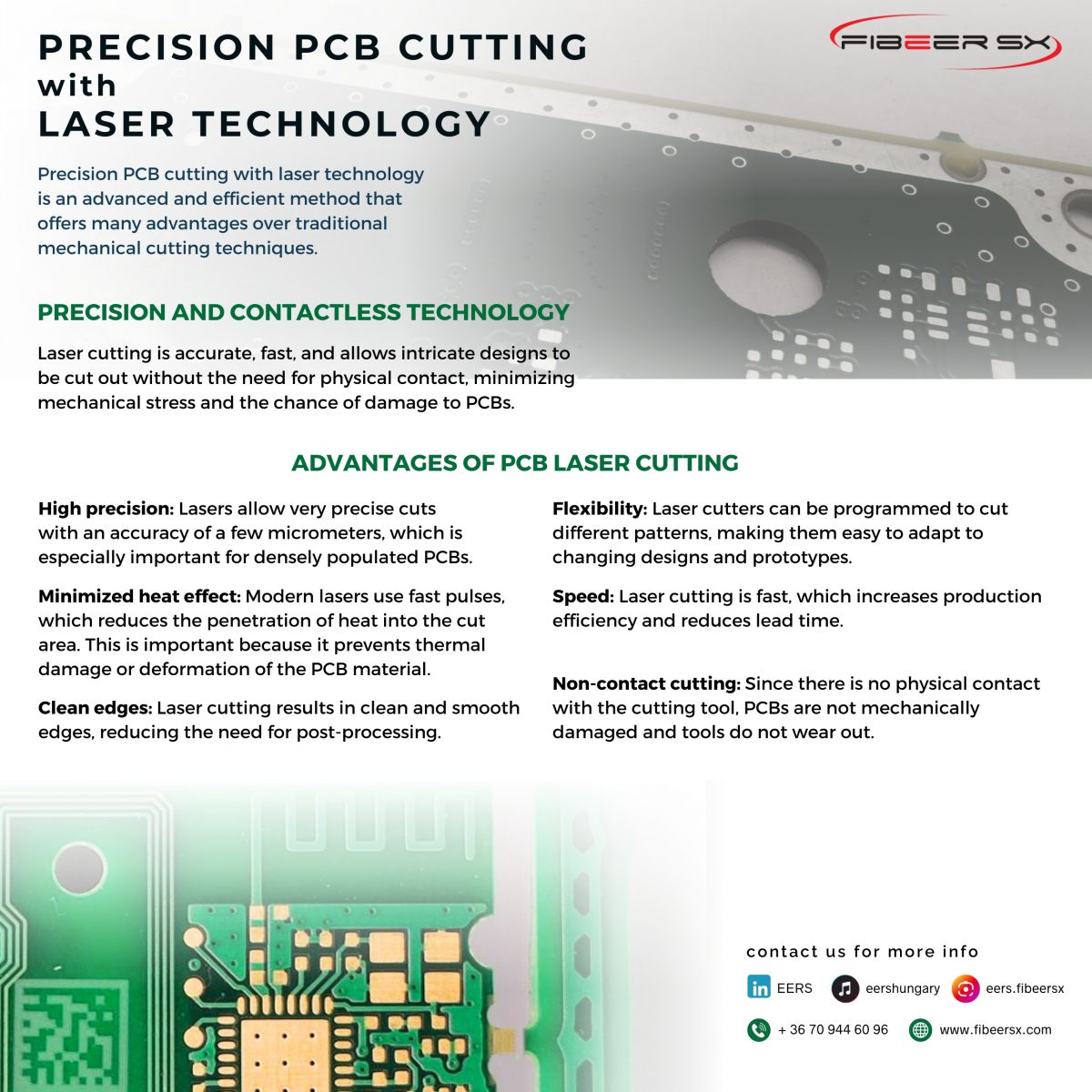

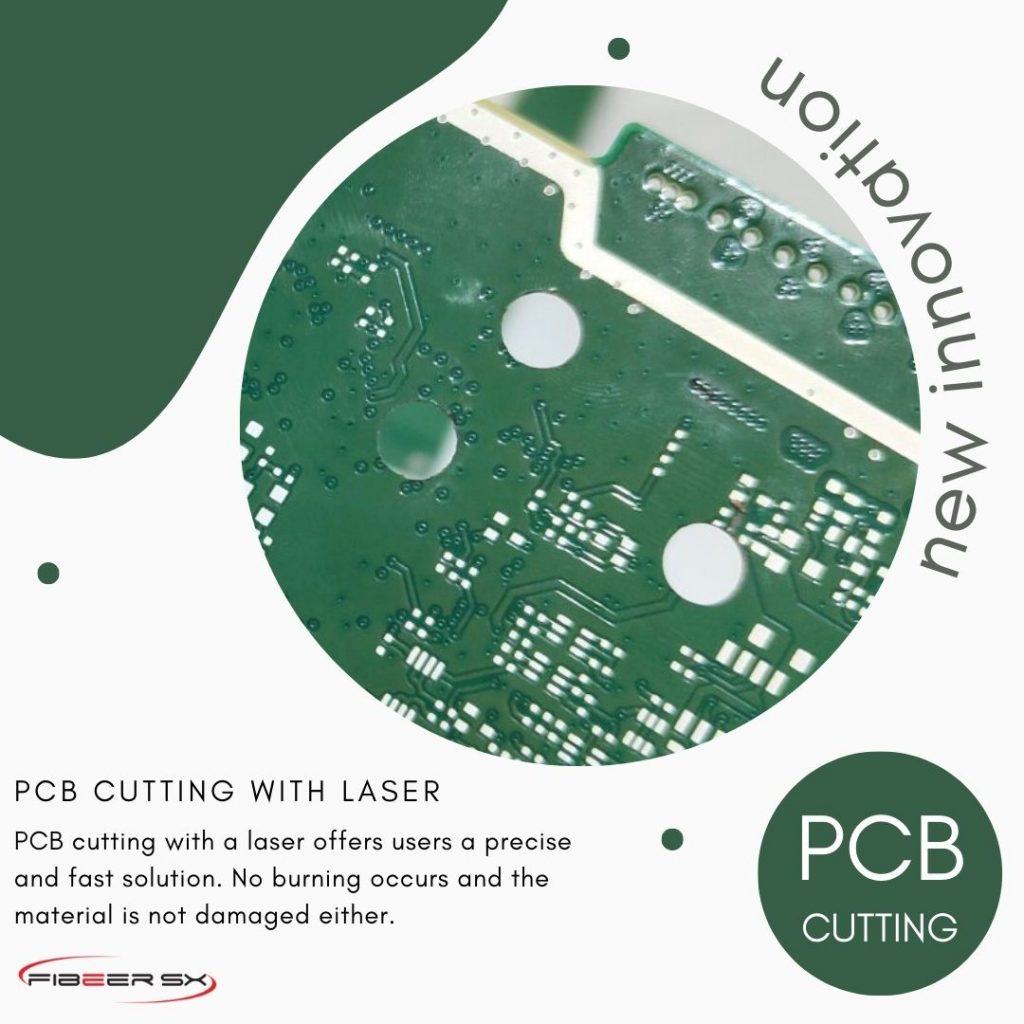

Thanks to its own program, our FibereSX laser equipment handles vector graphics well, so it is ideal for milling complex shapes and forms, and is capable of achieving micron-scale detail.