Multifunctional laser technology is a truly versatile and powerful tool that is widely used in various industrial applications because of its ability to integrate multiple capabilities into a single system. This integration offers significant benefits in terms of efficiency, accuracy and flexibility.

Milling

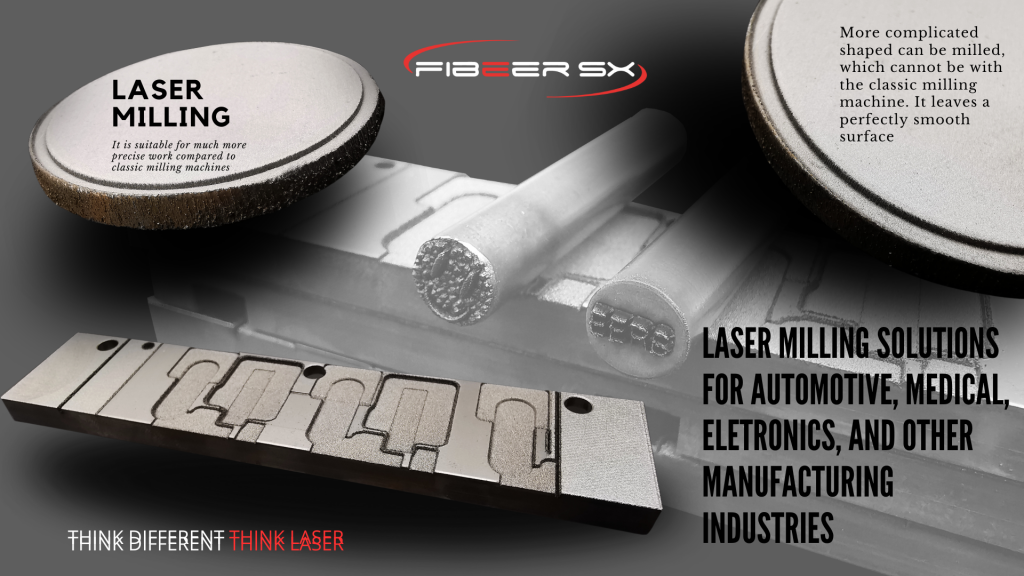

Laser milling uses a laser to remove material from the workpiece in a controlled manner. This process is ideal for creating complex shapes and patterns with high precision. With the laser, you can achieve fine details that are difficult to achieve with traditional milling tools.

Marking

Laser marking is used to record information or patterns on the surface of materials. This technique is often used for branding, serialization, and barcoding on a variety of materials, including metals, plastics, ceramics, and glass. The marks created by lasers are durable and wear-resistant.

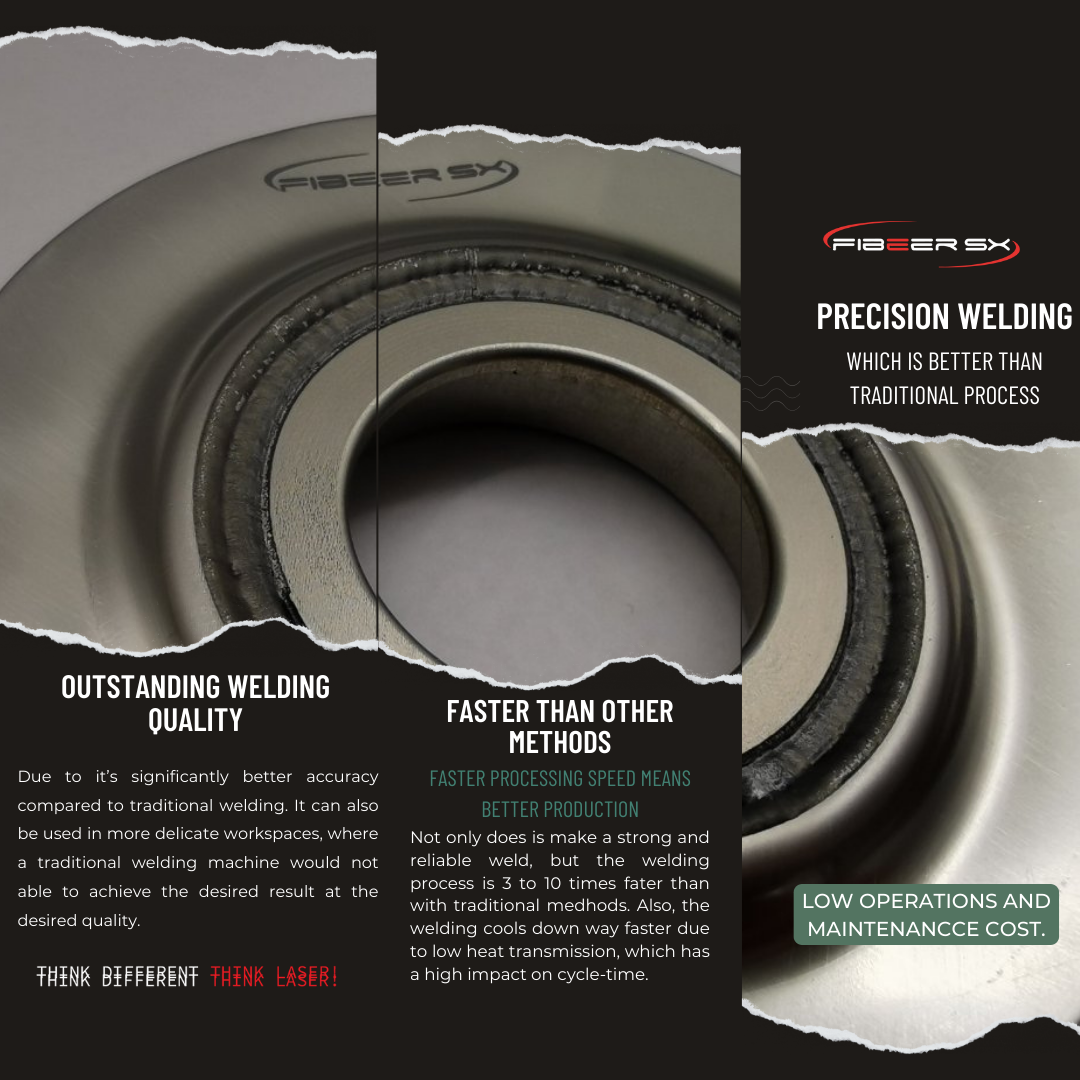

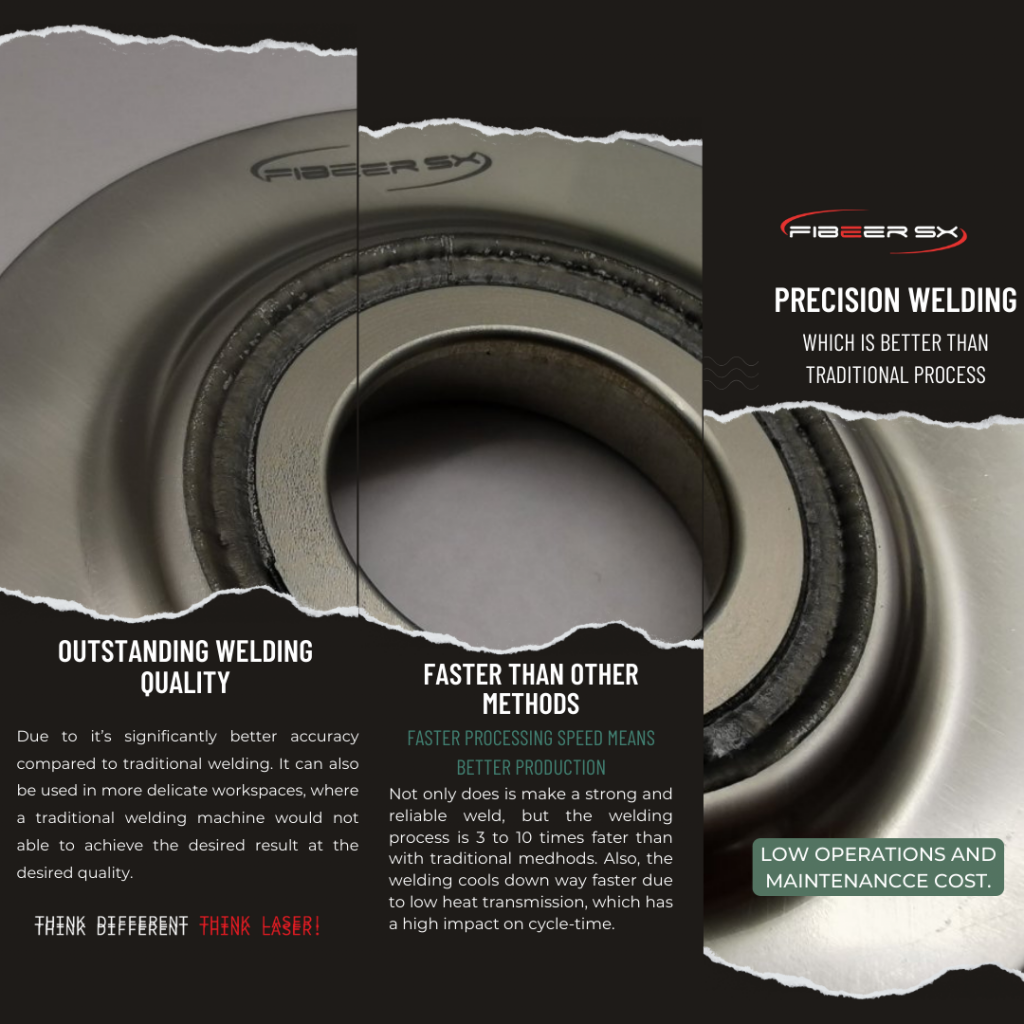

Welding

Laser welding uses a focused laser beam to join materials together. This method is known for its accuracy and can produce high quality, strong welds with minimal thermal distortion. It is particularly useful in industries where clean and precise welds are required, such as the automotive, aerospace and medical device industries.

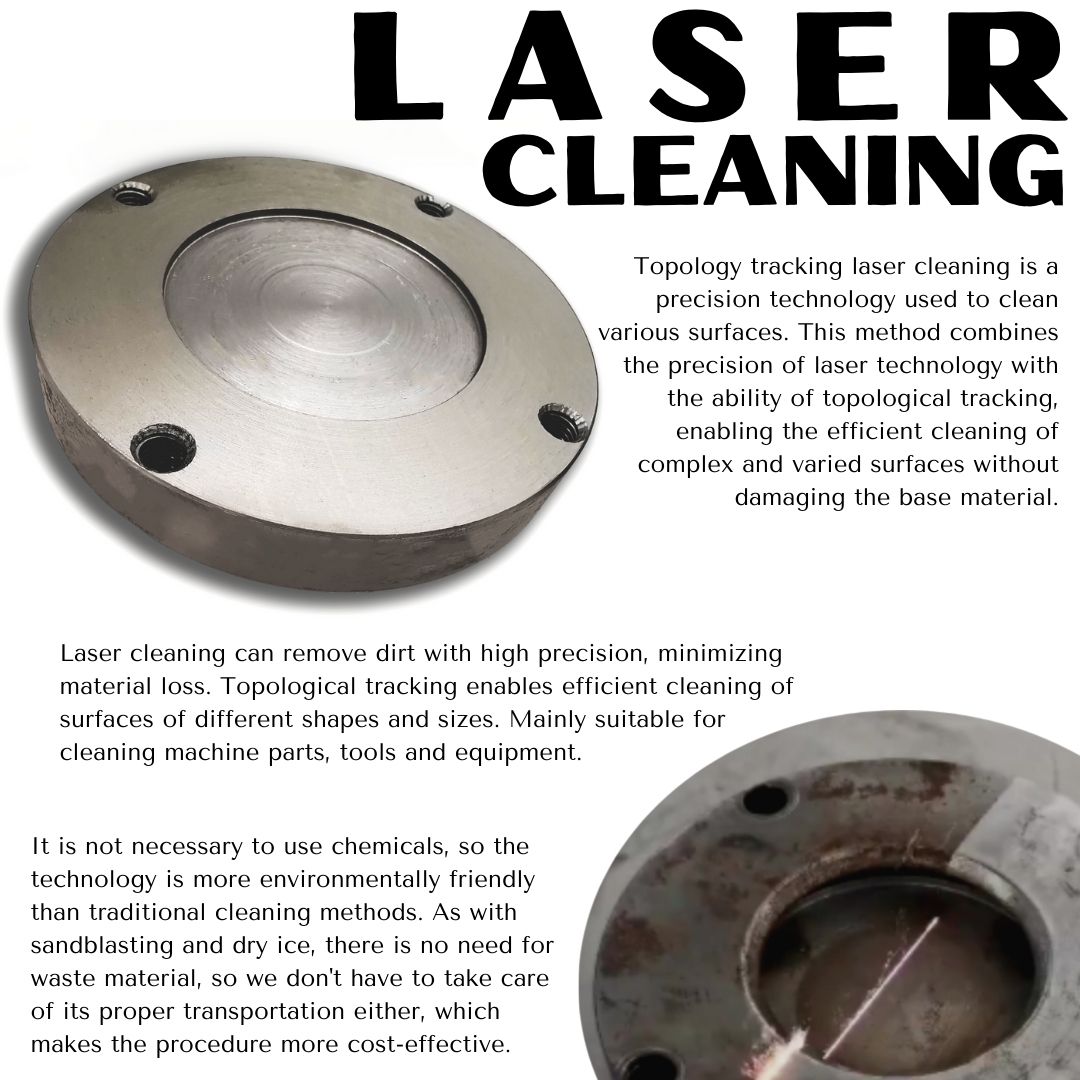

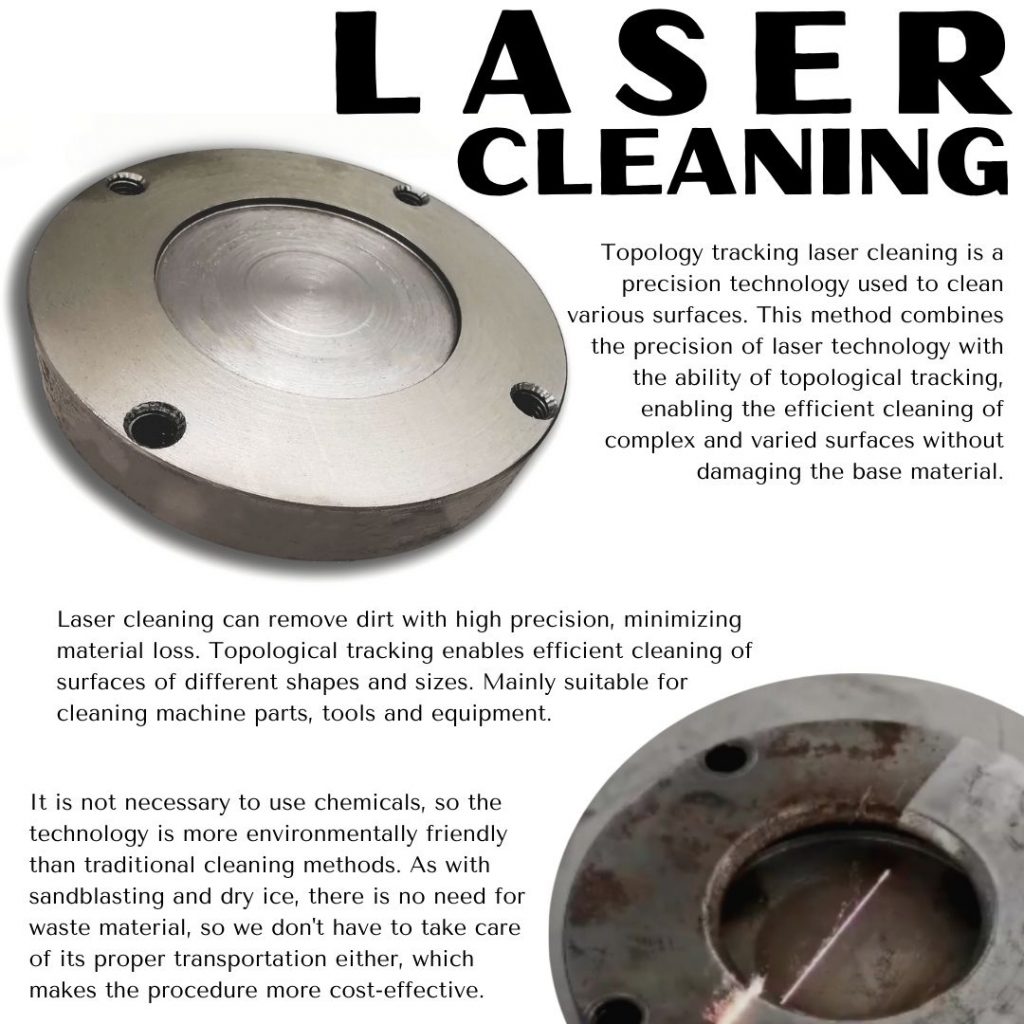

Cleaning

Laser cleaning is a process that uses laser pulses to remove dirt, rust, paint and other unwanted materials from surfaces. This method is environmentally friendly as it eliminates the use of chemical solvents and is highly effective in preparing surfaces for further processing or inspection.

Cutting

During laser cutting, a powerful laser beam is used to cut materials into the desired shape and size. This technique is widely used in industries such as metal fabrication, automotive, and electronics because of its ability to cut through various materials with high precision and speed.

Advantages of multifunctional laser technology

Precision and accuracy: Lasers offer unmatched precision and produce intricate details with high repeatability.

Efficiency: Integrating multiple functions into a single system reduces the need for multiple machines and setups, saving time and money.

Flexibility: A single laser system can be adapted to perform different tasks, making it a versatile tool for different applications.

Quality: Laser processes often result in high-quality surfaces with minimal post-processing required.

Environmentally friendly: Laser cleaning and processing often reduces the need for harmful chemicals and minimizes waste.

Industrial applications

Automotive industry: For welding parts, marking parts with serial numbers, cutting complex shapes and cleaning before assembly.

Aerospace Industry: For precision welding of parts, marking of parts for traceability and cutting of light materials.

Medical device manufacturing: For precision cutting of complex parts, welding of delicate parts and marking devices with unique identifiers.

Electronics manufacturing: for cutting and drilling PCBs, marking electronic components and soldering connectors.

Multifunctional laser technology is constantly evolving and offers even more opportunities and applications in various industries. Its ability to integrate multiple functions into a single system makes it an indispensable tool in modern manufacturing and processing.

Laser paint removal does not require chemicals or solvents that can be harmful to the environment and health. Since the laser process has no mechanical contact, less waste is generated during the process and there is no need to handle hazardous materials.

Laser paint removal does not require chemicals or solvents that can be harmful to the environment and health. Since the laser process has no mechanical contact, less waste is generated during the process and there is no need to handle hazardous materials.

Material selection

Material selection