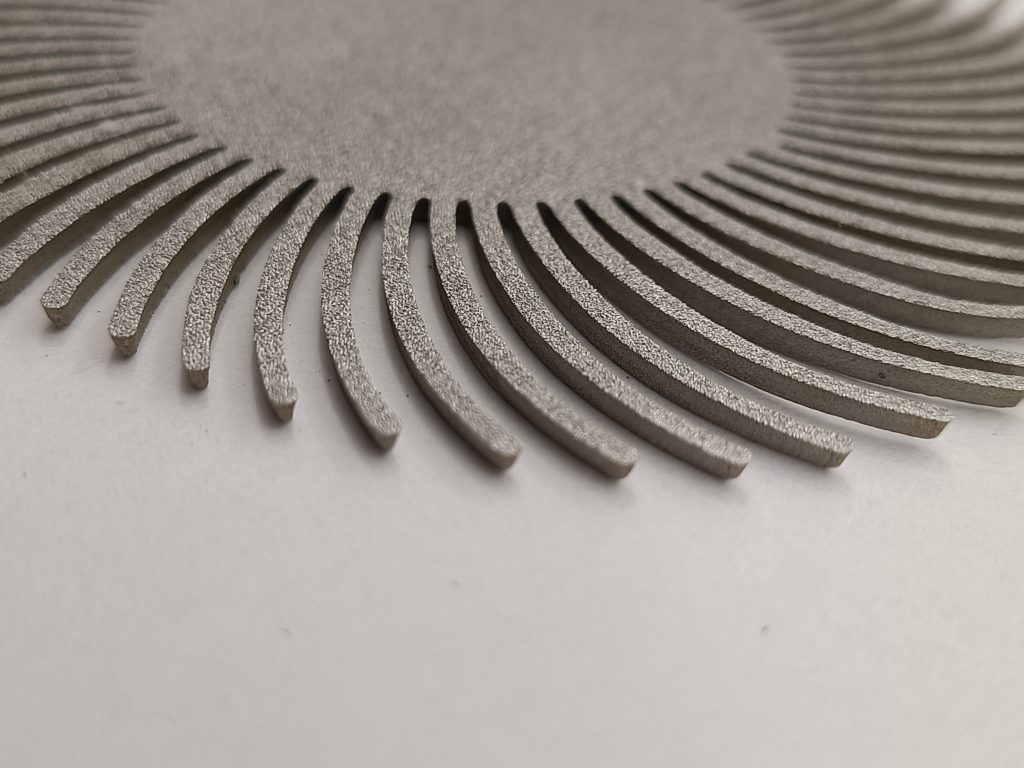

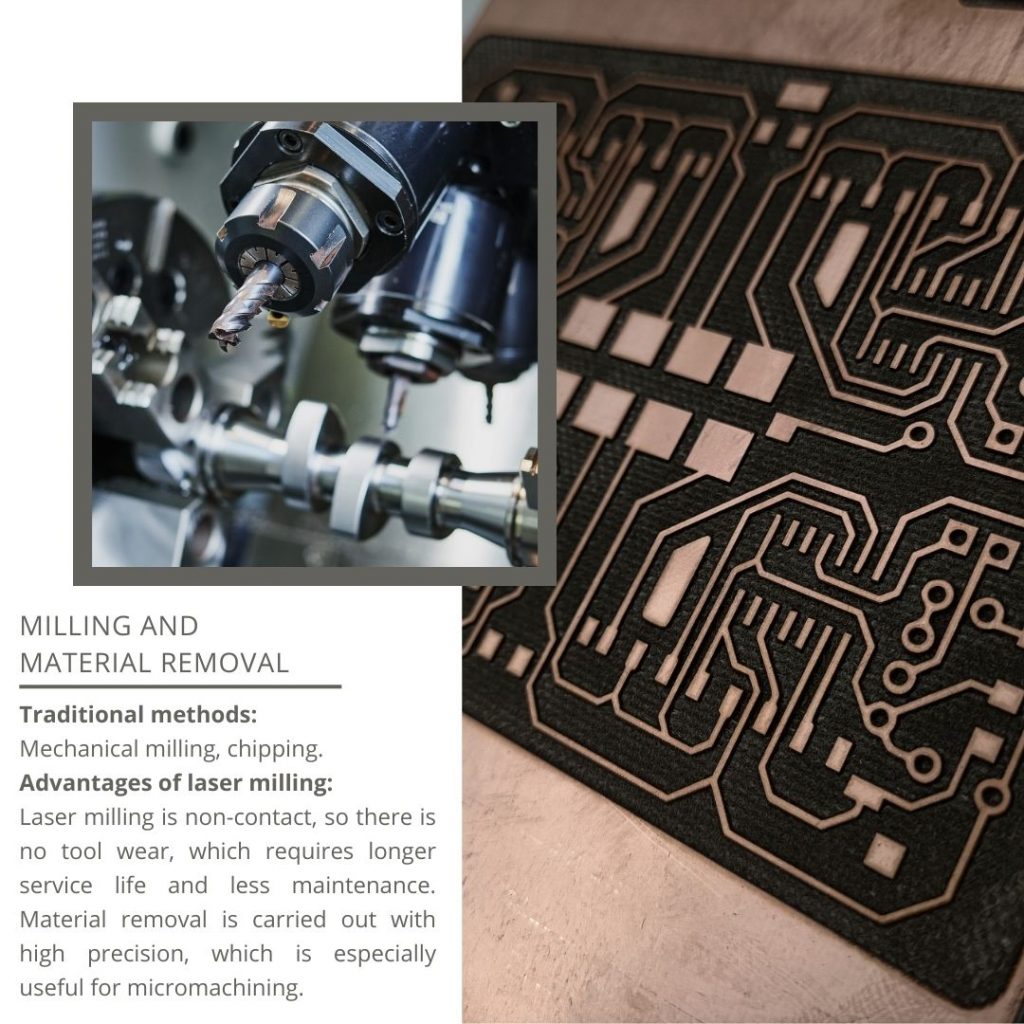

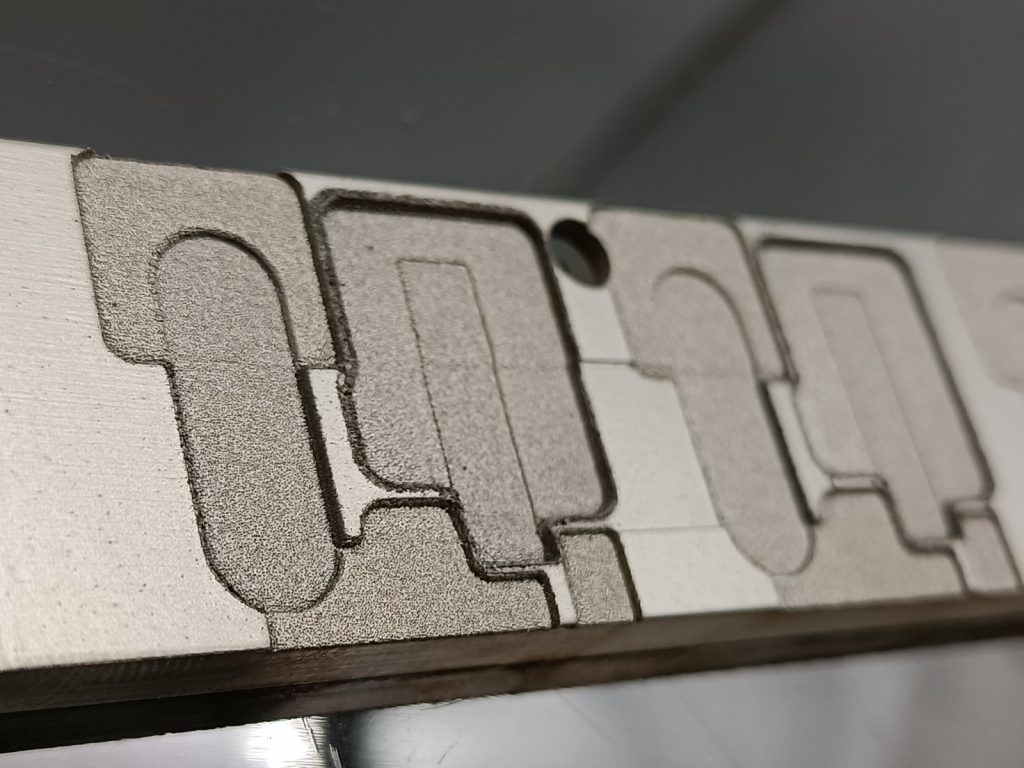

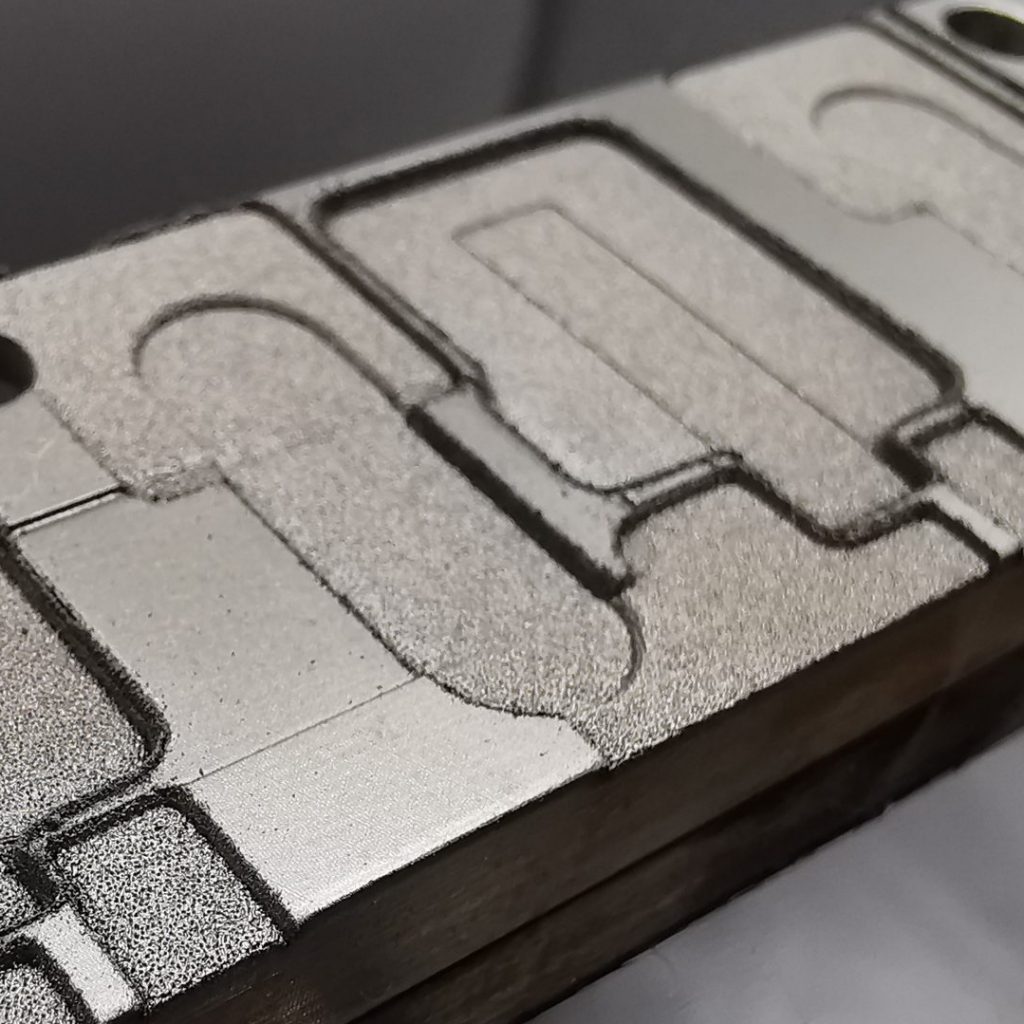

Greater precision and accuracy

It enables extremely fine and precise milling, often with tolerances in the range of microns. This is better than conventional milling, which can struggle to maintain such tight tolerances, especially for hard materials like titanium.

Minimal tool wear

In conventional milling, cutting tools wear out quickly when machining titanium due to its strength and hardness. Non-contact, eliminates physical wear of cutting tools, reduces tool change downtime and related costs.

Complex geometries

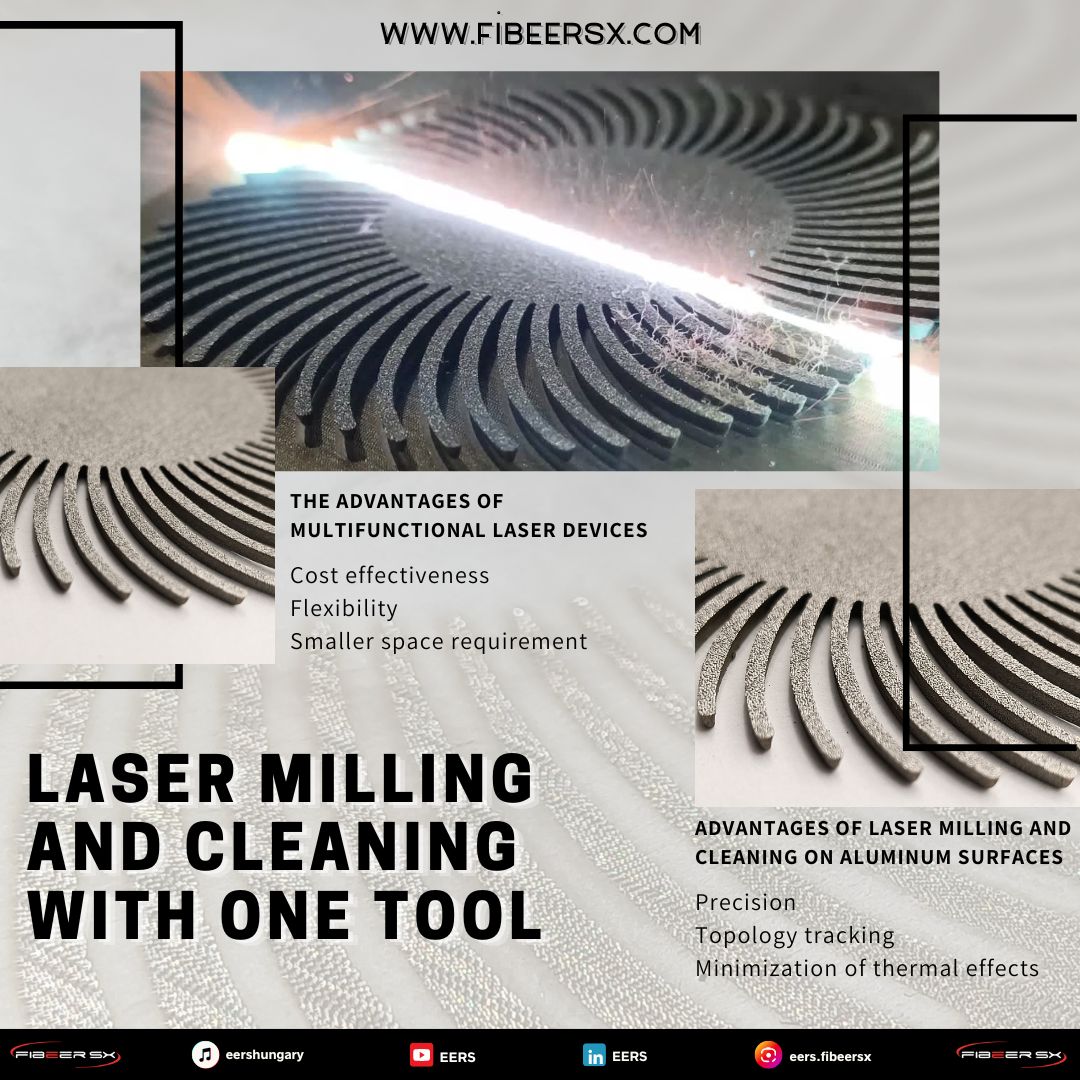

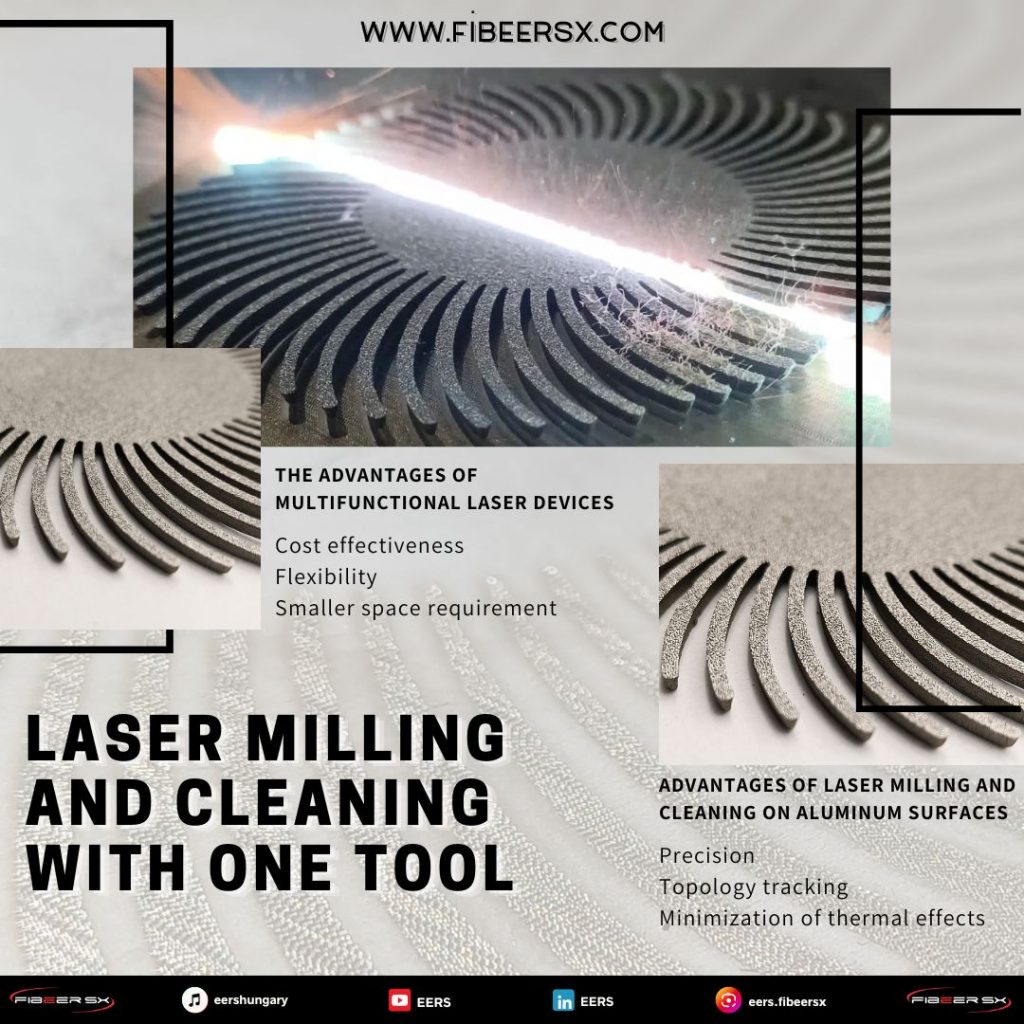

Laser milling can create complex and highly detailed geometries that are difficult or impossible to achieve with conventional milling. It is excellent for producing complex shapes, internal features or undercuts that require advanced techniques.

Faster processing times

It often operates at higher speeds than conventional mechanical milling, especially when machining thin layers of material. The speed and efficiency of laser milling is particularly beneficial in high volume or mass production environments.

Reduced heat effect zone

Despite the high temperatures, precision lasers can focus heat into extremely small areas, reducing the heat-affected zone around the milled area. Conventional milling produces heat through friction, which can cause deformation or affect the properties of the material over time, especially in the case of titanium.

Less material waste

Laser milling is extremely precise and can remove material in very thin layers, minimizing waste. Conventional milling often requires a larger cut, resulting in more waste, which is especially expensive when working with expensive materials such as titanium.

No physical force or vibration

Traditional milling exerts considerable force on the material, which can distort especially delicate parts. Laser milling is a non-contact process that eliminates mechanical stress, vibration or force that can affect the structural integrity of the part.

Better surface treatment

Lasers can produce a smoother surface compared to traditional cutting tools, reducing post-processing such as grinding or polishing that is often required in traditional milling.

Automation and flexibility

Laser milling systems are easy to program and integrate with CAD/CAM software, allowing for greater automation and flexibility in manufacturing.

Reduced risk of contamination

Because lasers do not require cutting fluid or direct contact, there is less risk of contamination on the titanium surface. Conventional milling often requires cutting fluid, which can cause contamination or require additional cleaning steps.

Scalability

Laser milling can be easily scaled for a variety of applications, from prototyping to large-scale production, with minimal modifications. Traditional milling can require significant retooling and setup changes to achieve the same scalability.

These advantages make precision laser titanium milling particularly useful in high-performance industries such as aerospace, medical devices and automotive, where precision, material integrity and efficiency are key.

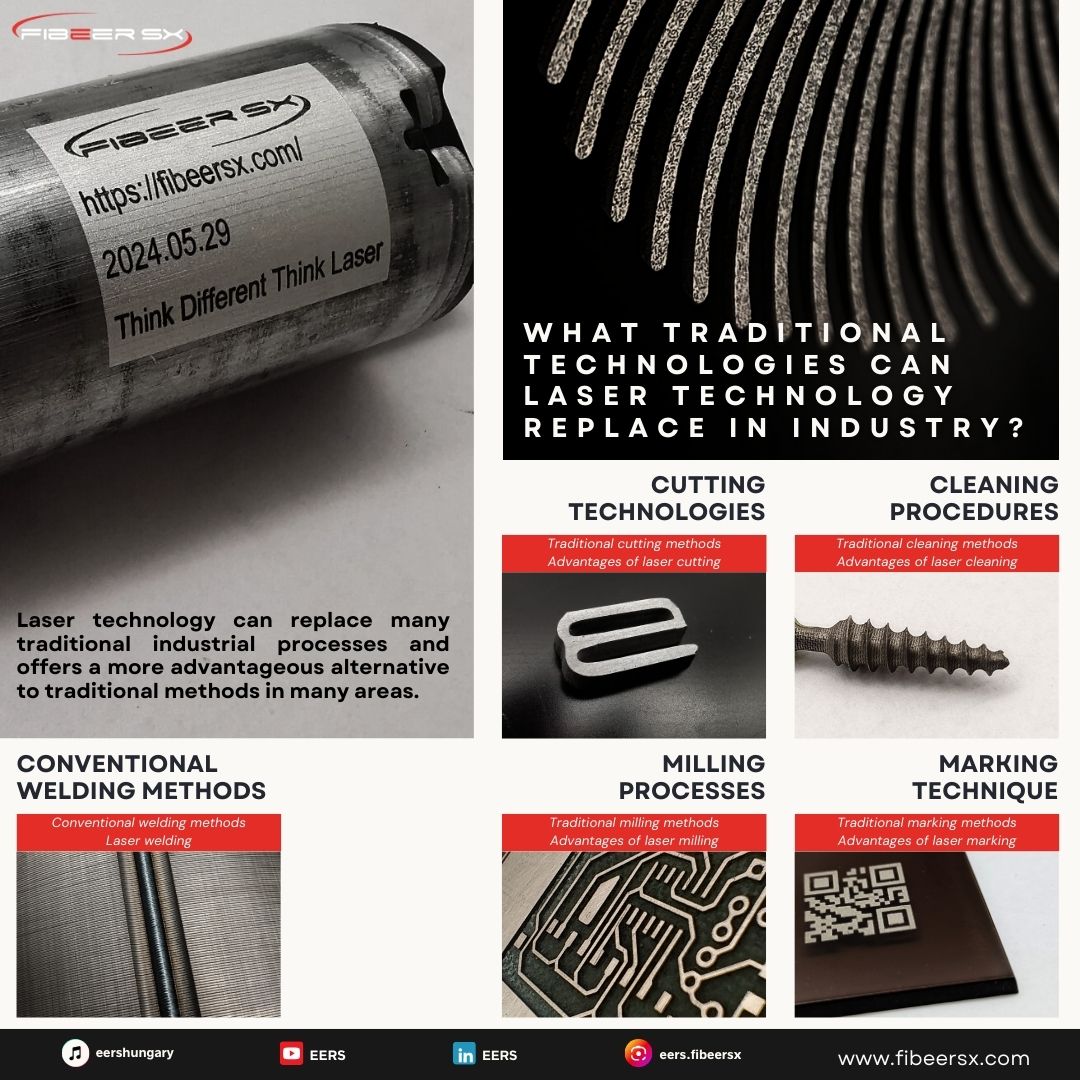

Laser cutting is one of the most widely used technologies in industry, thanks to its exceptional speed and accuracy. The process enables precise cutting of various materials with minimal material loss. It causes less deformation in the material and often does not require post-processing, which further increases efficiency.

Laser cutting is one of the most widely used technologies in industry, thanks to its exceptional speed and accuracy. The process enables precise cutting of various materials with minimal material loss. It causes less deformation in the material and often does not require post-processing, which further increases efficiency.