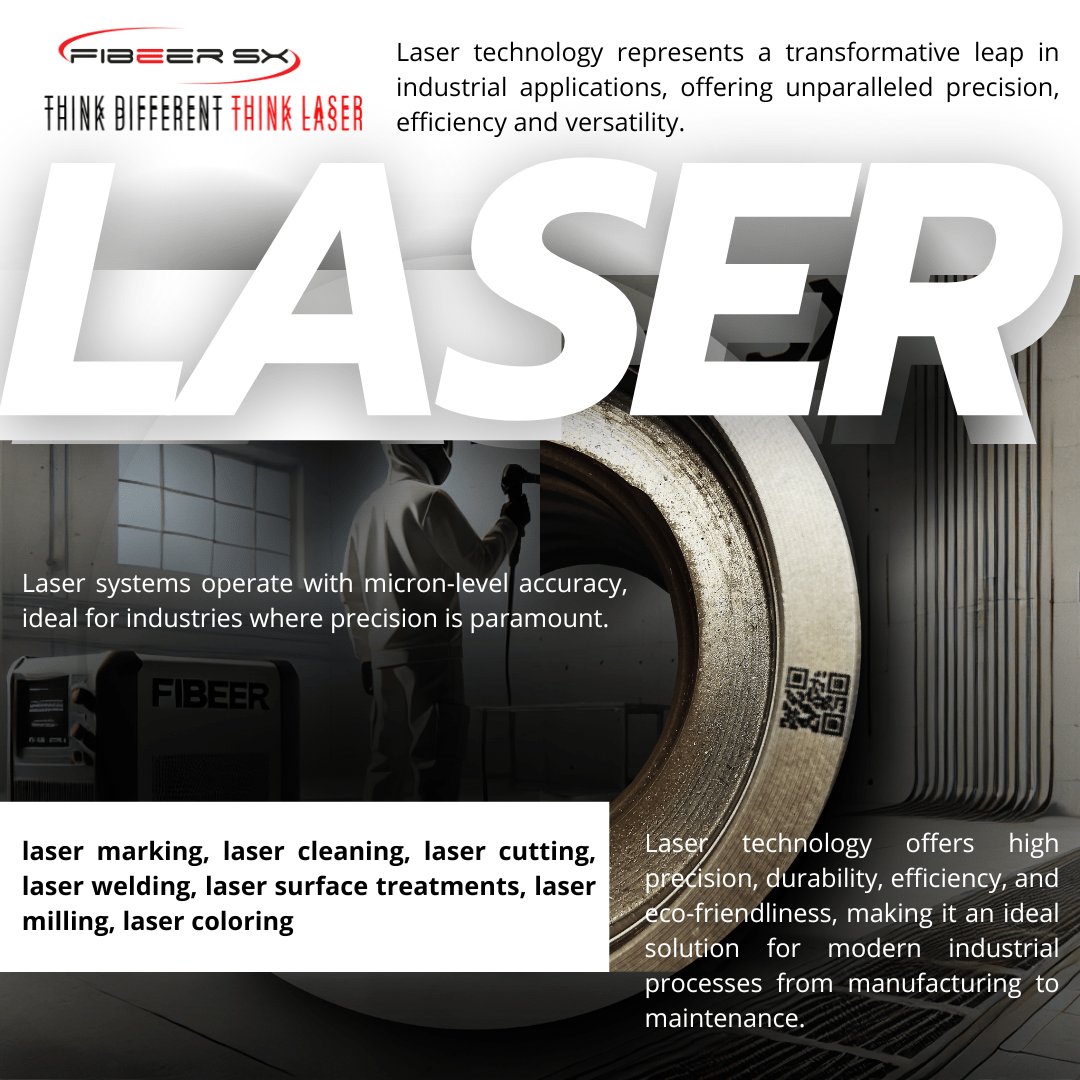

Revolutionizing Industry with Laser Technology

Laser technology represents a transformative leap in industrial applications, offering unparalleled precision, efficiency, and versatility. With micron-level accuracy, laser systems have become indispensable in sectors where precision is critical, from aerospace and automotive to electronics and restoration. At FIBEER SX, we believe in pushing boundaries — “Think Different, Think Laser.” Our cutting-edge laser systems redefine […]

Eco-Friendly and Cost-Effective: The Advantages of Laser Technology

In today’s fast-paced industrial world, manufacturers are constantly seeking sustainable and cost-efficient solutions. Laser technology has emerged as a game-changer, offering eco-friendly and low-cost alternatives to traditional manufacturing processes. Why is Laser Technology Eco-Friendly? Unlike conventional methods that rely on chemicals, consumables, or excessive energy, lasers work with precision and minimal waste: ✅ No harmful […]

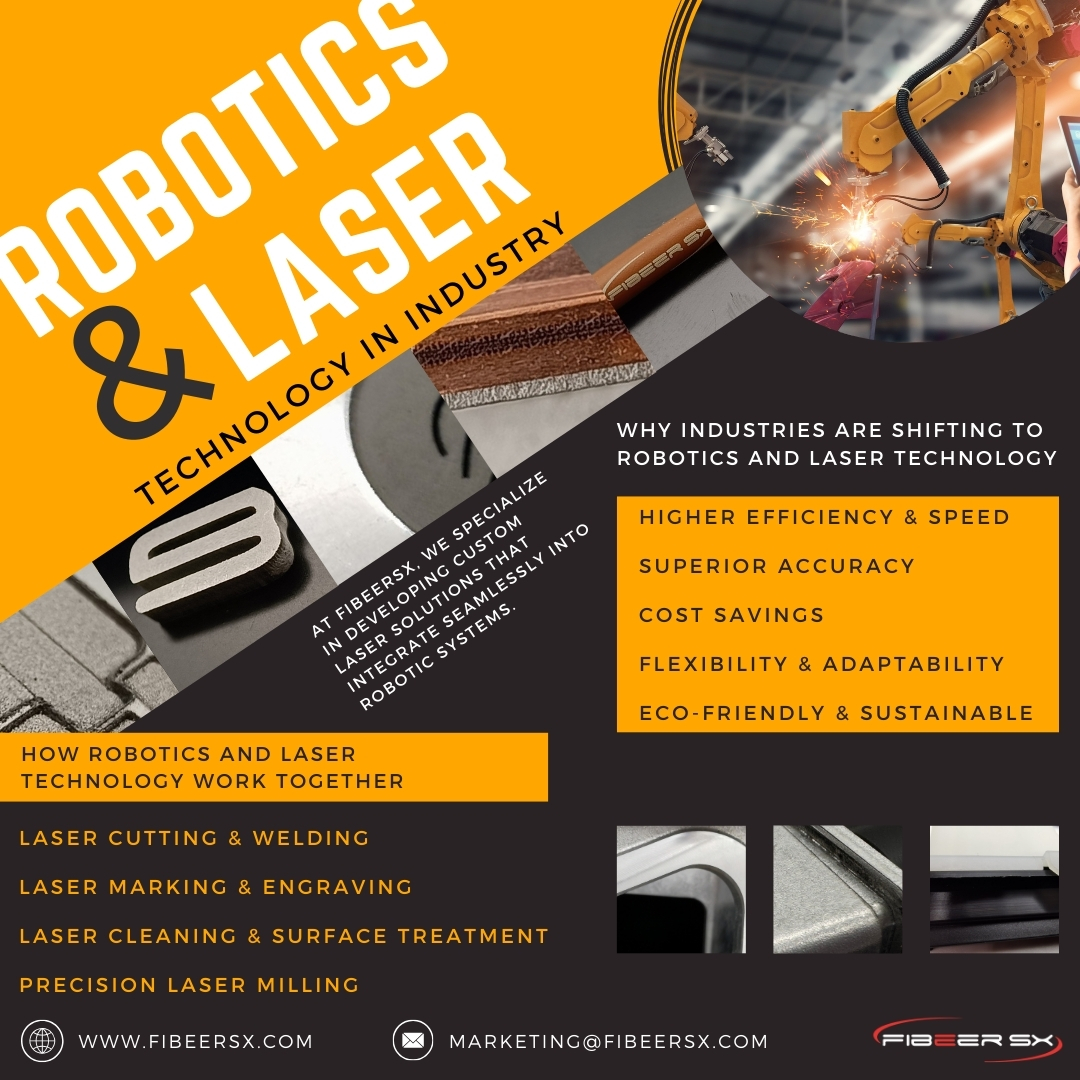

Robotics and Laser Technology in Industry – The Future of Precision Manufacturing

The integration of robotics and laser technology is transforming modern industrial processes, offering unparalleled precision, efficiency, and automation. From automotive manufacturing to aerospace engineering, companies are leveraging these cutting-edge technologies to optimize production, reduce waste, and improve product quality. How Robotics and Laser Technology Work Together By combining robotics and laser systems, industries can automate […]

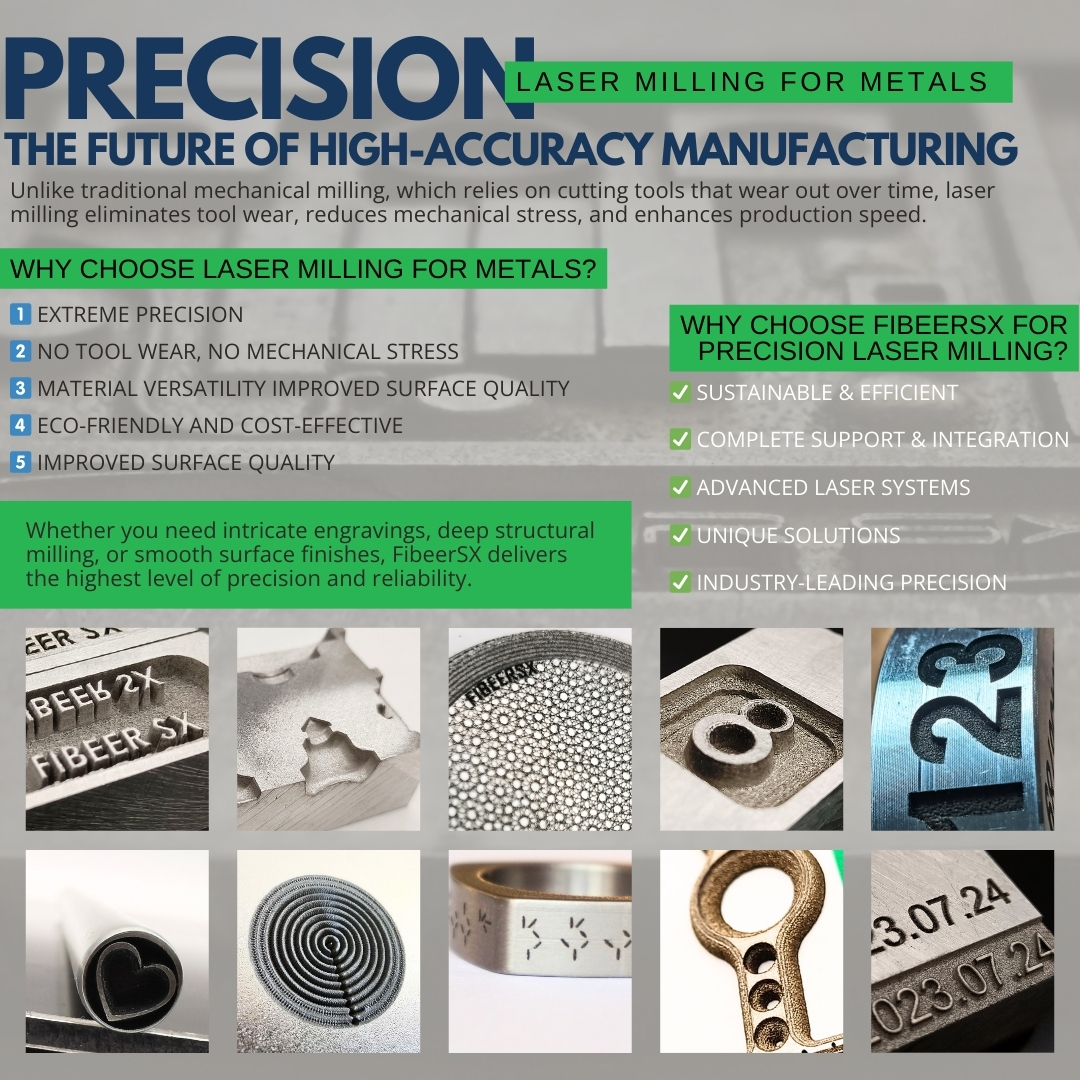

Precision Laser Milling for Metals – The Future of High-Accuracy Manufacturing

n modern manufacturing, precision is everything. Whether in aerospace, automotive, medical, or industrial applications, components require micron-level accuracy and flawless surface finishes to meet strict industry standards. This is where laser milling technology comes into play, offering a cutting-edge solution for machining metals with unmatched precision and efficiency. What is Precision Laser Milling? Laser milling […]

Versatile Laser Milling: From Rubber to Titanium

Laser milling is a cutting-edge technology that offers unparalleled precision and versatility across a wide range of materials. Whether working with soft, flexible rubber or high-strength metals like titanium, laser milling ensures accurate, contact-free material removal without causing unnecessary stress or deformation. One of the biggest advantages of laser milling is its adaptability. In industries […]

FibeerSX Team- Complete technical support from concept to integration

The application of laser technology is becoming more and more widespread in industry, but choosing and implementing the right solution can be a serious challenge. The FibeerSX Team aims to provide our partners with full technical support – from ideation, testing, implementation and integration. 🔹 Ideation and consultation – Analysis of individual needs and production […]

Revolutionizing Plastic Welding with Fibeersx Laser Technology Precision. Automation. Contactless Welding.

Thanks to continuous improvements, welding plastic parts has never been easier, more precise or more efficient. A new era in plastic welding Traditional plastic welding methods often come with challenges such as uneven joints, high heat loads and time-consuming processes. However, our innovative laser-based solution eliminates these drawbacks by offering a seamless, contact-free and fully […]

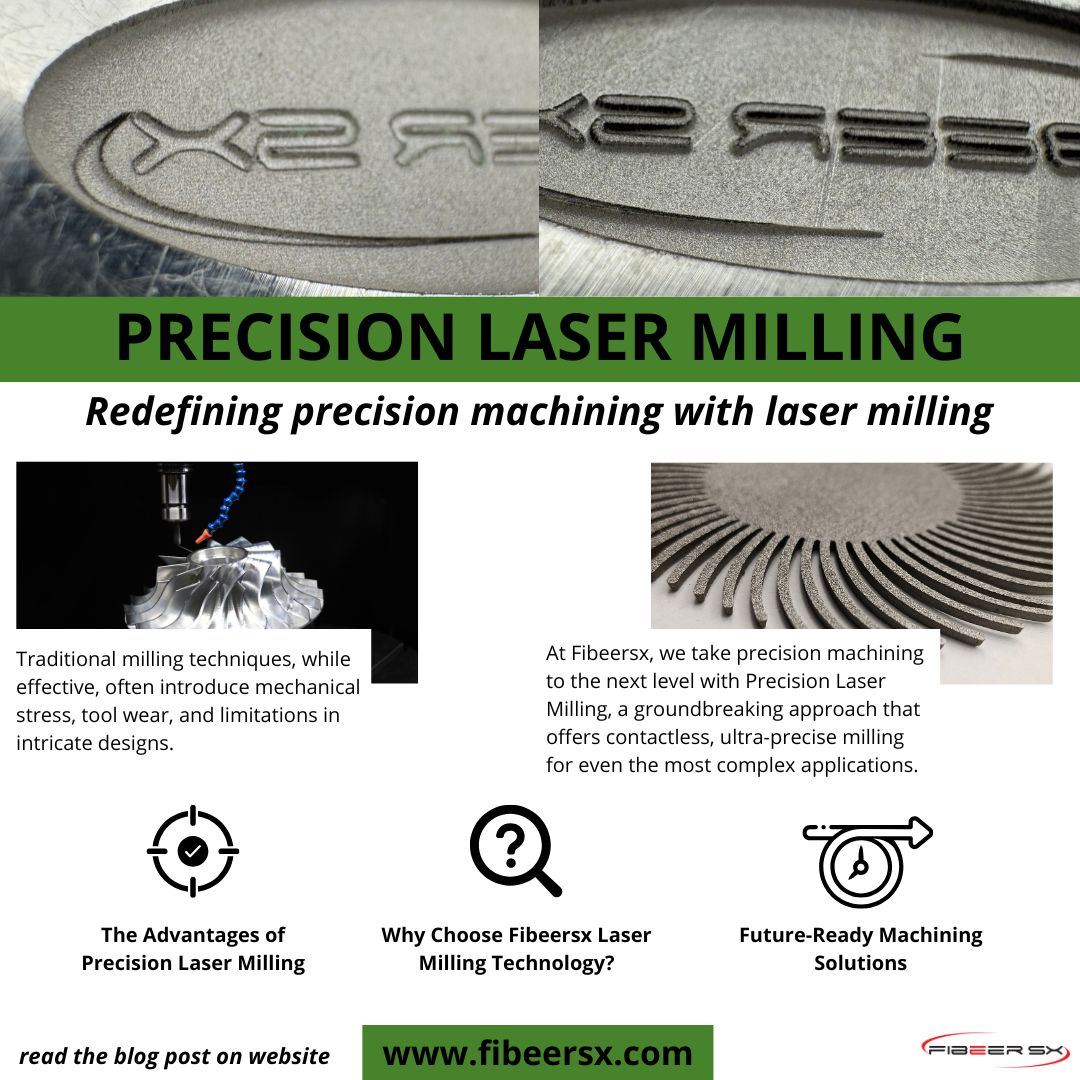

Fibeersx Precision Laser Milling

Unmatched Accuracy & Efficiency Redefining Precision Machining with Laser Milling In today’s competitive industrial landscape, achieving superior accuracy, minimal waste, and high efficiency is paramount. Traditional milling techniques, while effective, often introduce mechanical stress, tool wear, and limitations in intricate designs. At Fibeersx, we take precision machining to the next level with Precision Laser Milling, […]

Precision PCB Cutting with Fibeersx Laser – Unmatched Accuracy & Efficiency

Printed Circuit Board (PCB) manufacturing demands exceptional precision, as even the slightest error can impact performance. Traditional cutting methods, such as mechanical routing or milling, often introduce stress, burrs, and material waste. The Fibeersx laser cutting system offers a superior alternative, ensuring clean, accurate, and damage-free PCB processing. Why Choose Fibeersx Laser for PCB Cutting? […]

Advantages of Fibeersx

FibeersX offers cutting-edge solutions in laser technology with several advantages that cater to industrial needs. Advanced Laser Solutions: Multifunctional laser devices designed for cleaning, welding, cutting, marking, and engraving, ensuring high precision and efficiency. Customizable Equipment: Modular designs that can be tailored to meet unique client requirements, ensuring flexibility for diverse industrial applications. Sustainability: Energy-efficient […]

unique laser development

Thanks to our advanced laser development, we offer near-endless variations in functionality and application. Our innovative approach ensures that our laser systems are not only versatile but also highly adaptable to a wide range of industrial needs. Test request form What Makes Our Laser Systems Unique? Our dedication to continuous improvement and customization makes us […]

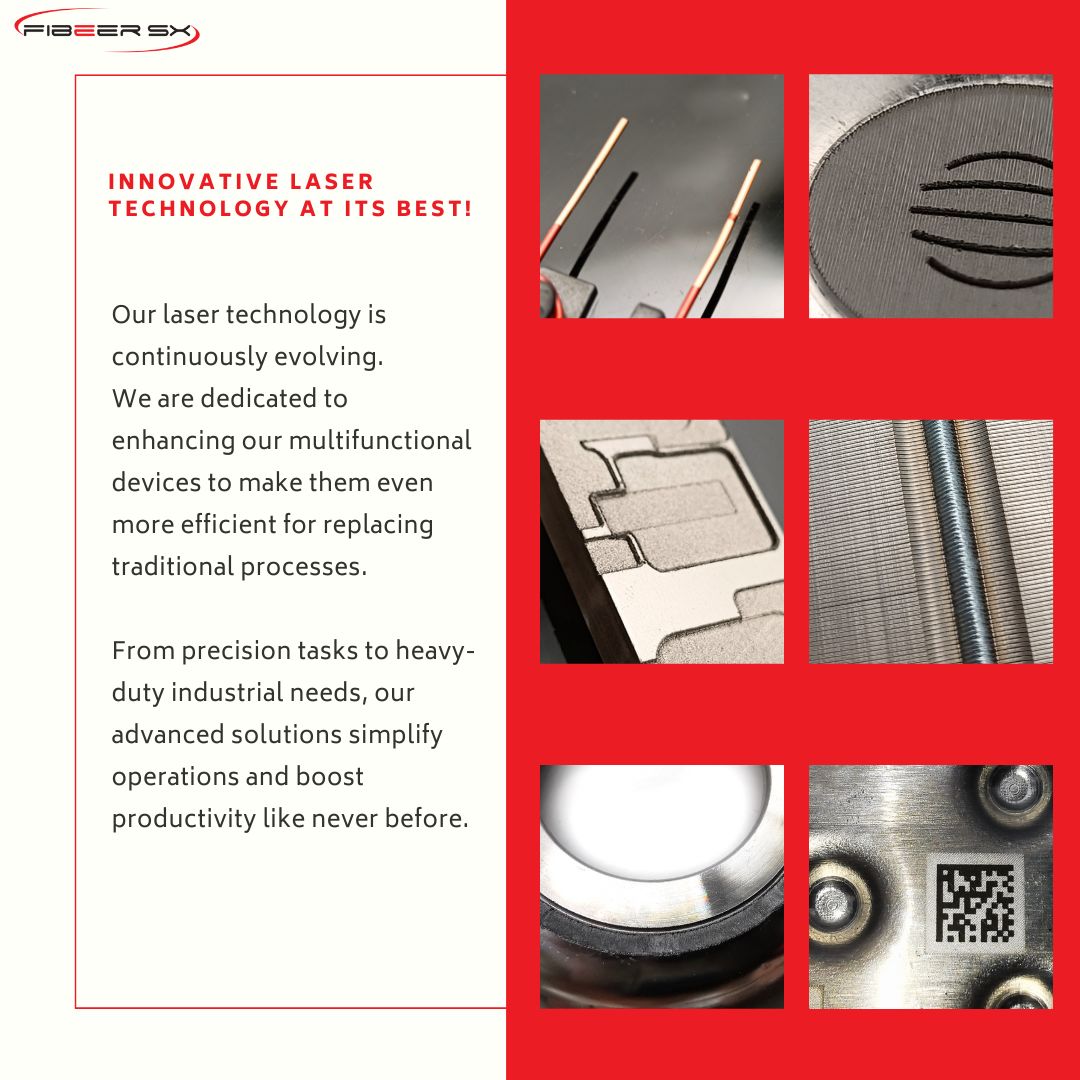

Innovative Laser Tecchnology

Laser technology represents a transformative leap forward in industrial applications, offering unmatched precision, efficiency, and versatility. At its core, laser technology leverages focused light energy to perform tasks with extreme accuracy, making it a game-changer across multiple industries. Test request form Future Enhancements in Laser Technology Innovation in laser systems is a continuous process. Upcoming […]