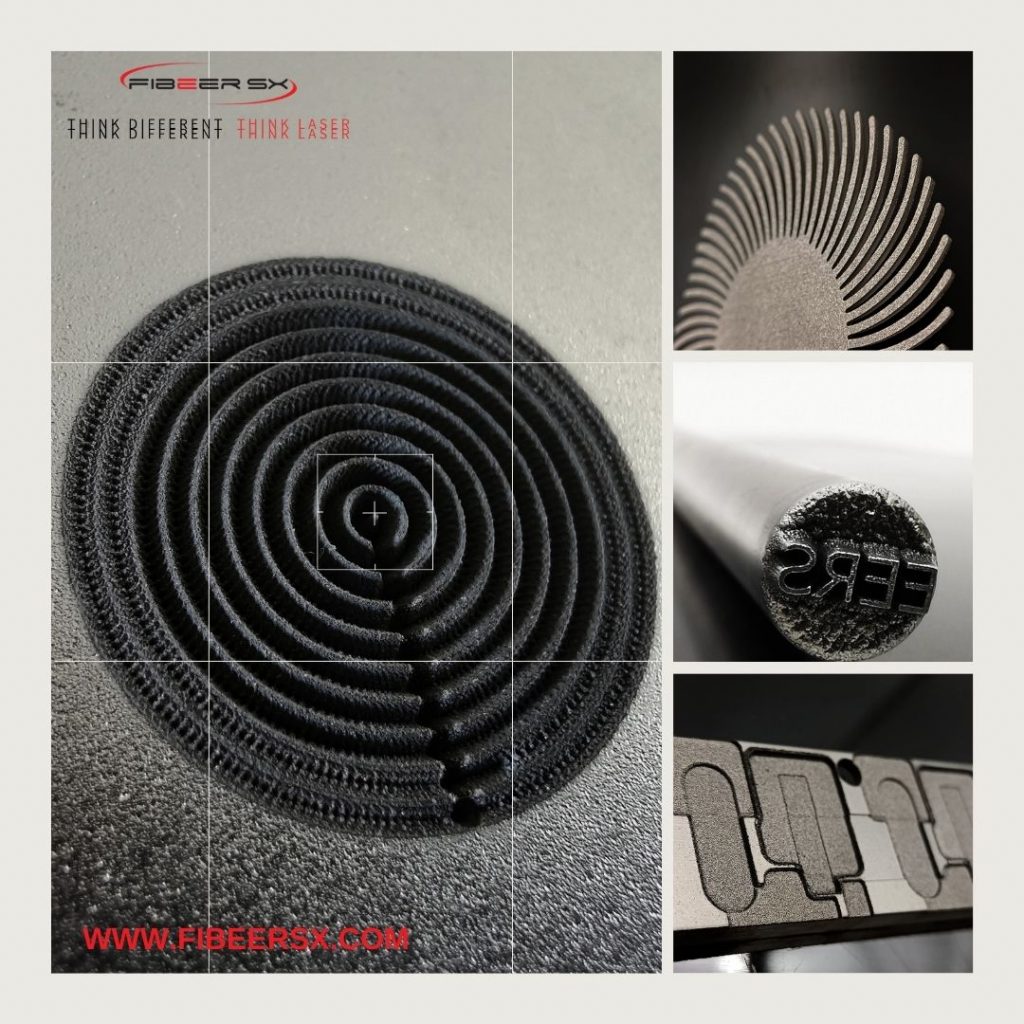

Laser milling is a modern processing technology that uses laser beams to remove material from the base material. During the process, we can create different patterns, shapes, inscriptions, we can even create differences in levels, because the laser cutter can trace the topology. Thanks to our unique development, we can also do 2D and 3D laser milling, and thanks to our program, we can also mill complex patterns and shapes. The technology also has many advantages over traditional milling technologies, especially precision, micron-accurate milling, speed and versatility.

Laser milling is a modern processing technology that uses laser beams to remove material from the base material. During the process, we can create different patterns, shapes, inscriptions, we can even create differences in levels, because the laser cutter can trace the topology. Thanks to our unique development, we can also do 2D and 3D laser milling, and thanks to our program, we can also mill complex patterns and shapes. The technology also has many advantages over traditional milling technologies, especially precision, micron-accurate milling, speed and versatility.

Advantages:

High accuracy and precision: Thanks to the programming, it handles vector graphics well, making it ideal for milling complex shapes and forms, and capable of micron-sized detail.

Speed: It works with excellent speed on both thinner and thicker materials, reduces milling time, thereby increasing productivity.

Material selection: It can be used in a wide range of applications, from plastic to metals, the equipment can also grind on more sensitive materials, as it can be tuned very finely, so the sponge won’t burn either.

No Tool wear: The process is non-contact, so there is no tool wear, which reduces maintenance costs and downtime.

Clean and Smooth Milling: There are no burrs during milling, so there will be no waste. During the process, only dust is generated, which is removed from the milling area by suction, so it is an environmentally friendly solution. The result is an excellent surface quality, which requires minimal post-work or can even be dispensed with.