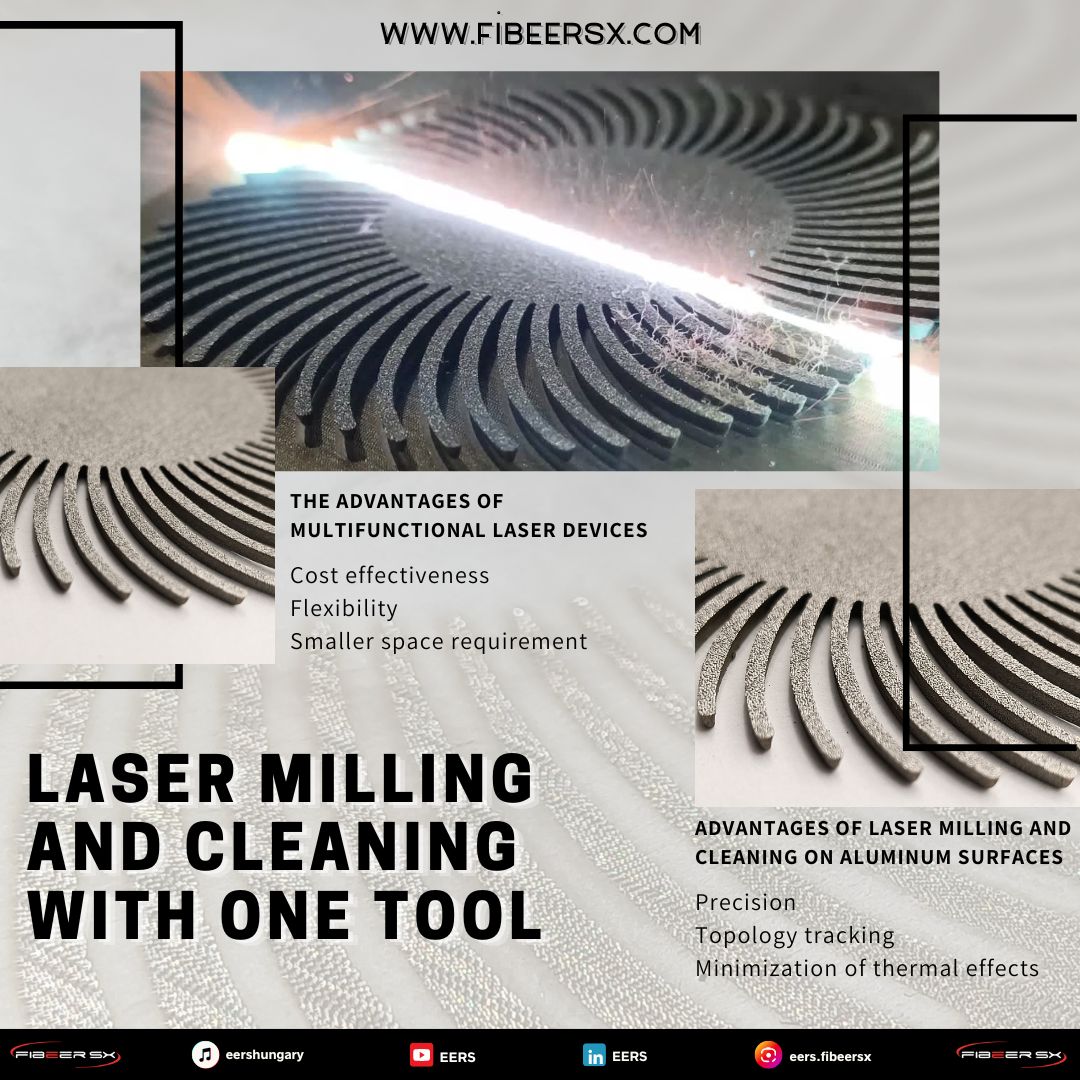

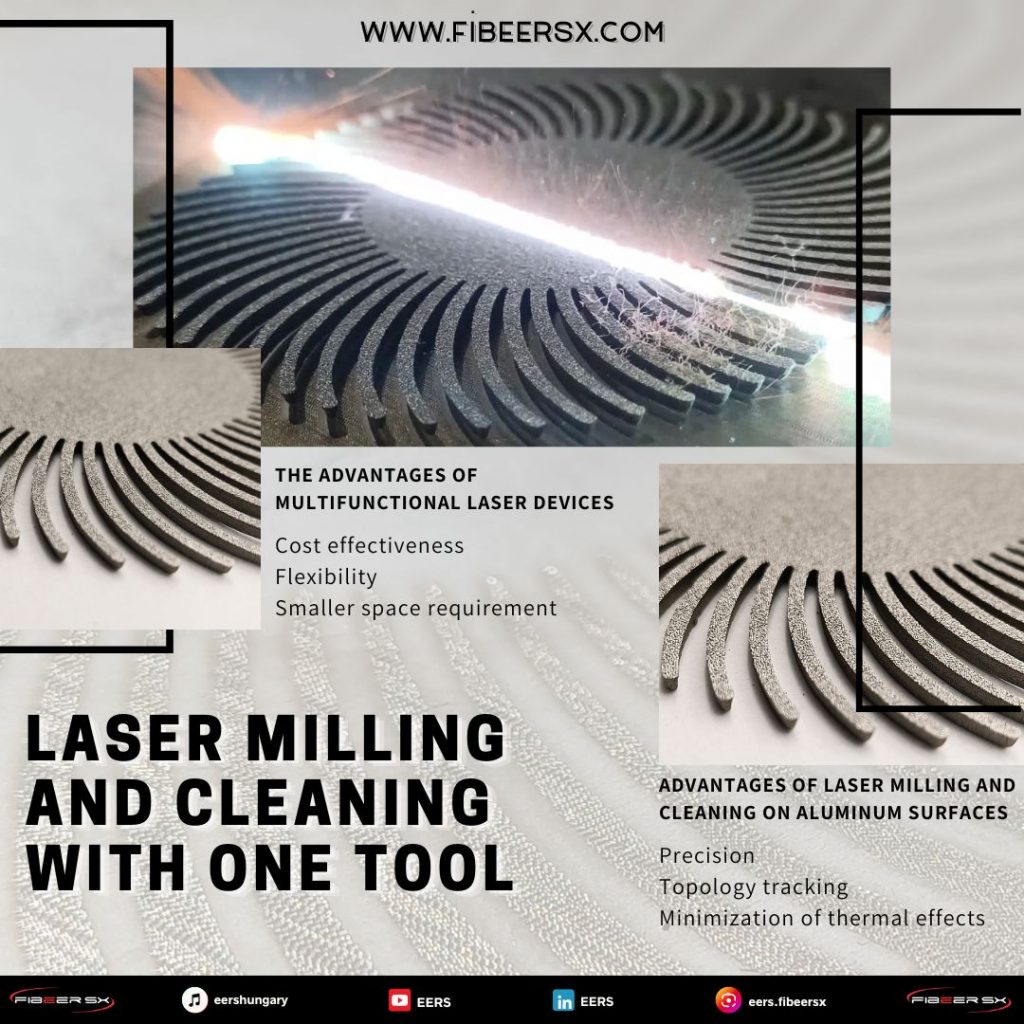

Thanks to the development of our multifunctional laser devices, they are able to perform multiple tasks with a single device, such as milling and cleaning. This is a big step forward in industrial processes, as it provides both cost-effectiveness and flexibility in various manufacturing and maintenance tasks.

Advantages of multifunctional laser equipment

Cost effectiveness

Since a single piece of equipment can perform several tasks, there is no need for several different machines, reducing acquisition and maintenance costs.

Flexibility

The tools easily perform various tasks such as milling and cleaning, so they can quickly adapt to production needs.

Smaller space requirement

Since one piece of equipment performs more functions, it takes up less space on production lines, which is especially beneficial in tighter production environments.

Advantages of laser milling and cleaning on aluminum surfaces

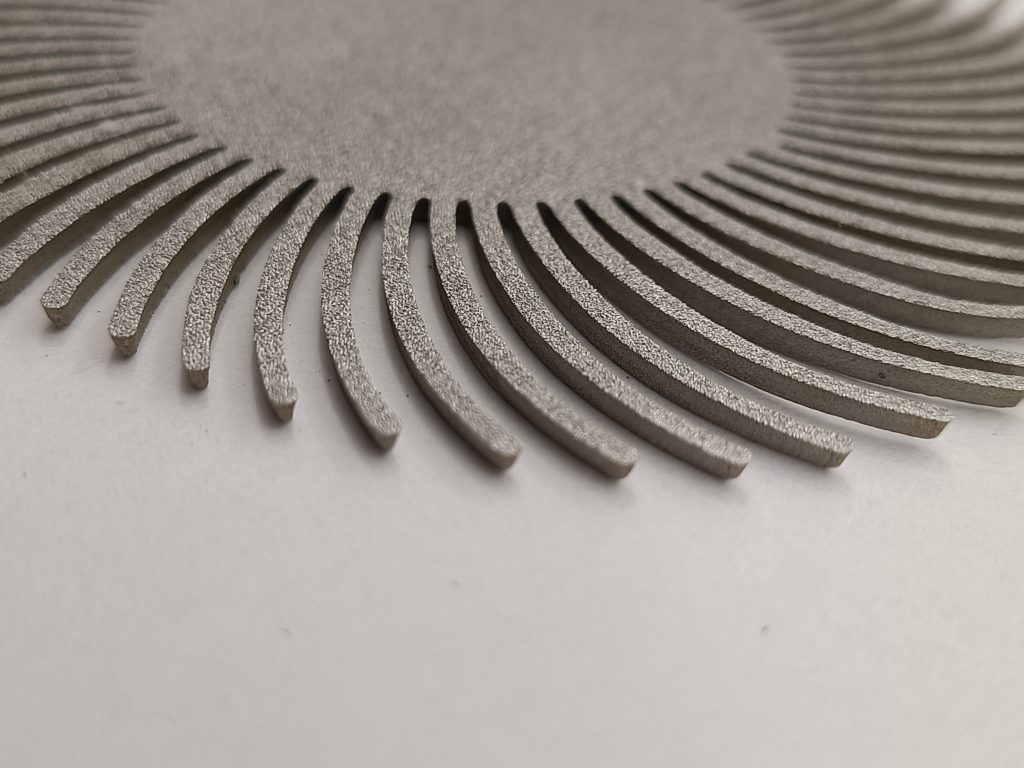

Precision

The fine precision of the laser beam allows the creation of small details and complex patterns on aluminum surfaces, while working without contact, thus avoiding deformation of the material and a cleaning process after the milling process.

Topology tracking

Laser cleaning precisely follows the contour of the surface, even if it is complicated or difficult to access. During the milling process, the layers are gradually and precisely removed, preserving the integrity of the surface.

Minimization of thermal effects

Laser technology works with minimal heat, which is especially important for aluminum, as this material is sensitive to heat-induced deformation.